1. Introduction.

Automation of stages of sewing design products remains one of the topical scientific trends in the garment industry. But, despite the rapid pace of general automation of the production process, the stages of constructive modeling of complex cuts clothing are still carried out in manual or semi-automatic mode. This can be explained by the fact that the work at the modeling stages is based on the creative analysis and personal experience of the designer [1]. Stages of modeling are difficult to algorithmize. It is necessary to focus on the introduction of intellectualization methods into this process to automate these stages. The methodology of solving this problem has already been considered in a number of papers [2,3,4,5]

The basic principles of intellectualization of the automated engineering process of clothing designs are theoretically determined on paper [6]. However, in practice this issue has not been fully implemented. At present, the vector of CAD for clothes development is shifted towards the implementation of 3D graphics, leaving behind the «creative» specifics of the garment designer’s work in 3D space [7].

2. Materials and Methods.

A study of the traditional manual modeling process of three-dimensional clothes was conducted to develop methods of constructive modeling of complex garments details in an automated intellectual environment. As a research subject, a short sleeve with pinches on the cap and the bottom of sleeve (sleeve-flashlight) was chosen.

3. Results and Discussion.

Based on the results of the study:

— parametric characteristics of the structure were defined and systematized [8], through which the dialogue is organized between the automated system and the designer (Table 1);

— an algorithm for constructing a design that allows to automate fully the stage of modeling was developed.

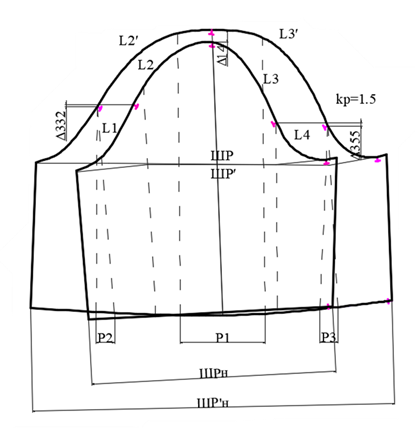

The system of parametric characteristics of the sleeve-flashlight construction contains the necessary information on the planar sweep and the volumetric form of the sleeves. The developed system of parameters is structured in accordance with the sequence of actions of the designer and the decisions made by him, while developing the models of clothing (Table 1, Figure 1).

Table 1

System of parameters for the description of MC (model construction) of sleeves with pinches on the cap and the bottom of sleeve

| N | Сoefficient | Description of the parameter |

| 1 | 2 | 3 |

| 1 | Шр | The initial width of the sleeve at the depth of the cap (Basic Construction) |

| 2 | ∆ Шр | Size of sleeve extension |

| 3 | Шр’ | The width of the model sleeve at the level of the depth of the cap (MK) is Шр’ = Шр + Δ Шр |

| 4 | kp | Coefficient of extension of a sleeve |

| 5 | Шрн | The initial width of the sleeve at the bottom (BC) |

| 6 | Шр′н | The width of the model sleeve on the bottom (MC) |

| 7 | Др | The length of the basic construction of sleeve (BC) |

| 8 | Др′ | Length of model sleeve (MC) |

| 9 | Вок | The initial height of the sleeve cap (BC) |

| 10 | ∆14 | The value of raising the highest point of the sleeve |

| 11 | Вок′ | Height of the model cap of a sleeve (MC) Bok ‘= Bok + Δ14 |

| 12 | ∆14x | The value of the displacement of the highest point of the cap of the sleeve (with an irregular pinch on the front and back sections) |

| 13 | ∆332 | The value of displacement of the beginning point of the sleeve extension in the back upper part of the cap |

| 14 | ∆355 | The value of a displacement of the beginning point of the sleeve extension in the front upper part of the cap |

| 15 | L1 | The initial line, describing the lower back part of the sleeve cap (BC) |

| 16 | L4 | The initial line describing the lower front part of the sleeve cap (BC) |

| 17 | L2 | The initial line, describing the upper back part of the sleeve cap (BC) |

| 18 | L3 | The initial line describing the upper front part of the sleeve hose (BC) |

| 19 | L2′ | A model line describing the upper back part of the sleeve cap (MC) |

| 20 | L3′ | A model line describing the upper front part of the sleeve hose (MC) |

| 21 | kc2 | The coefficient of pinches on the upper rear portion of the sleeve |

| 22 | kc3 | Coefficient of pinches on the upper front portion of the sleeve hose |

| 23 | ∆Дрн | Elongation of the sleeve along the midline of the sleeve at the bottom |

| 24 | Р1 | Extension in the middle section of the sleeve through the highest point of the cap |

| 25 | Р2=Р3 | Expansion of lateral areas along the front and back notches |

Figure 1. Parameters describing the MC of sleeve «flashlight»

The developed system of parameters will be used in developing dialog windows of the software product and for creating the bases of recommended parameter values. Using intuitively understandable and detailed characteristics in the process of automated design will allow the designer to be immersed into a creative working atmosphere and to take into account all aspects of modeling as much as possible.

In the process of developing a new algorithm for modeling a sleeve with pinches along the cap and the bottom of the sleeve, literature that covers the problem of modeling sleeves was studied. Methods that were analyzed are presented bellow:

1. Constructive modeling of clothes: Study letter for universities / AI Martynova, EG Andreeva — Moscow: Moscow State University of Design and Technology, 2006. — pp., from silt;

2. Technique of cutting. Eight hundred drawings of models, detailed drawings and visual diagrams / Lin Jacques; M .: RIPOL classic, 2009. — 592 p .: ill.

3. Modeling and designing of women’s clothing / Mueller and son; — 1 volume, Moscow: Publishing house «EDIPRESS-KONLIGA», 2008.-231 p .: ill.

4. Women’s clothing in detail / N. V. Erzenkova. — 3rd edition. — Mn .: «Polymya», 1992. — 320s.: Ill. ;

The absence of a universal method for obtaining a model hose design was revealed based on the results of the analysis of the modeling methods of the «flashlight» sleeve. A number of shortcomings are typical for modern techniques:

— Clear parameters and modeling coefficients are not specified;

— no recommendations are given for drawing a graphical contour of the sleeve construction.

The revealed shortcomings of the methods exclude the possibility of their use for the development of automated algorithms.

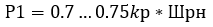

When developing a new algorithm for modeling a sleeve with pinches along the cap and the bottom of the sleeve, the shortcomings listed above were taken into account. The technique for constructing a sweep of a sleeve of a complex shape (Fig. 2) was developed on the basis of the parameters presented above (see Table 1). A special feature of this method is that it is completely mathematically describes all the stages of construction, which in turn makes this technique adapted for the automated design process.

1. Preparation of the BC sleeve for modeling (Fig. 2b):

a. Measurement of the sleeve on the bottom (Шрн)

b. Calculation of the extension of the sleeve with accounting the coefficient of extension relatively to the length of the bottom (cuff) of the sleeve. The value of the coefficients varies kр = 1.1-2.5 (depending on the design project).

c. From the highest point of the cap of the sleeve 14, the line of the warp thread is lowered

2. Dilution of the sleeve for a given amount of extension (Fig. 2c):

а. Parallel expansion of the middle section of the sleeve

By the notch 14 of the highest point of the cap of the sleeve, the BC is expanded in parallel for 70-75% with the extension P1.

b. Conical expansion of lateral areas

b. Conical expansion of lateral areas

The remaining 25-30% of the expansion are conically expanded along lines parallel to the line of the warp thread of a sleeve drawn from 332 and 335 evenly on the back and front.

3. Forming the sleeve cap:

a. Raising the cap of the sleeve, depending on the properties of the specified material from point 14 upwards

Δ14 = 0.5 … 5.0 cm

b. The cap of a sleeve is formed in three directions:

i. From point 332, the guiding line of the upper section of the back part of the sleeve cap matches with the guiding line of the corresponding back lower part;

ii. From point 335, the guiding line of the upper section of the front part of the sleeve cap matches with the guiding line of the corresponding front lower part;

iii. The guiding line at the highest point of the cap is horizontal and passes through 14′;

4. Forming the bottom of the sleeve

Forming the bottom of the sleeve occurs along two guides, matching the front and back parts of the bottom after conical expansion.

ΔDrn = 0.3 … 1.5 cm

Figure 2. Sequence simulation of the design of the sleeve «flashlight»

- BC of the sleeve drawing; b) application of the line of the warp thread and the line of the sleeve; c) parallel and conical expansion of a sleeve; d) forming the cap of the sleeve; e) forming a smooth curve of the bottom of the sleeve; f) MC of the sleeve flashlight drawing

References

1. Kiseleva M.V. Development of the parametric method of 3-D modeling of female belt products: dis. ... cand. tech. Sciences: 05.19.04 / M., MGUDT, 2011. - С45-61.2. Stages of the development of the method of automated design of decorative details of clothing with elements of intellectualization Murashova NG, Getmantseva VV, Andreeva EG Design. Materials. Technology. 2011. № 1 (16). Pp. 95-99;

3. Getmantseva VV, Strunevich E.Yu., Andreeva EG Intellectualization of the initial stages of designing clothing models // Design and technology. 2008, No. 9.-P.66-71 .;

4. Strunevich E.Yu. Development of a method for converting a creative sketch into a model design for the automated design of women's clothing: dis. ... cand. tech. Sciences: 05.19.04 / MGUDT. M., 2008. 240 p .;

5. Boyarov Mikhail Sergeevich DEVELOPMENT OF THE METHOD OF PARAMETRIC DESIGN OF THE SPATIAL FORM OF MEN'S SHOULDER PRODUCTS: dis. ... cand. tech. Sciences: 05.19.04 / MGUDT. M., 2013. p. 74-81].

6. Getmantseva V.V. Development of methods for intellectualization of the process of computer-aided design of women's clothing: dis. ... cand. those. Sciences: 05.19.04 / MGUDT. M., 2006. - P. 30 - 32.

7. Means of designing CAD for clothes with a view of 3D-specificity Boyarov MS, Getmantseva VV, Maksutova MT, Andreeva EG Design and technology. 2011. № 22 (64). Pp. 39-42;

8. Investigation of the parameters of the planar solution of model vtachnyh sleeves Goncharuk EO, Novoselova AV, Getmantseva VV