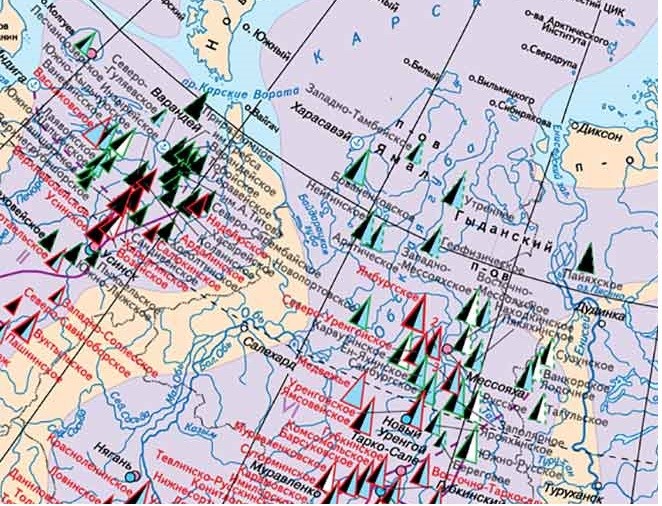

Looking at the maps of the distribution of minerals, it can be noted that most of the developed oil fields are located in Western Siberia and Tatarstan, while deposits in the Arctic zone and in the Arctic are actively studied and developed (Fig.1).

Figure 1. Developing oil provinces [2]

The most characteristic generalizing feature is permafrost (MMG), located under a layer of seasonal freezing-thawing. The stability and reliability of infrastructure facilities directly depend on the load-bearing capacity of MMG, which decreases with increasing temperature. Due to the degradation of the MMG, numerous problems have been identified and there are cases of partial or complete destruction of objects, while there is a danger for the most important infrastructure facilities in Russia.

The second reason is environmental. During the degradation of MMG, landslides, thermokarst subsidence develop, and the load-bearing capacity of highways, including highways serving oil fields, decreases (on average, according to our data, 1 oil well requires up to 30 trucks of standard load capacity 10-15 tons (KAMAZ) per day.

The third reason is the increase in greenhouse gas emissions, especially methane, during the melting of MMG, which can affect the carbon cycle and increase global temperature [10].

Drilling wells with the equipment of the drilled hole is a complex technological process and requires a significant amount of special drilling fluids. Waste solutions-oil sludge are formed both during the extraction of crude oil, and during its transportation and processing. On average, 1 thousand tons of crude oil «weighs» 5-7 tons of oil sludge [3].

Used for the treatment of drilling fluids and contained in the spent drilling mud, materials and reagents must have the toxicity indicators (MPC, MP, LD50, and others) agreed in accordance with the established procedure and the hazard class is not lower than the 3rd according to the current Federal classification catalog of waste [4].

The high humidity of drilling cuttings, mainly associated with the content of clay particles, which have a low filtration coefficient (less than 0.005 m / day) and a high water saturation coefficient (more than 0.75 cu), is the main cause of waterlogging of the area in the locations of sludge barns.

Existing technologies for the disposal of spent drilling sludge include the addition of cement or quicklime to the sludge accumulators to reduce the fluidity of the sludge. In the future, the spent sludge is selected from the storage tank and sent for disposal in accordance with the requirements of the supervisory environmental authorities. This technology, according to our calculations, leads to an increase in the cost of 1 ton of oil produced by 1.3-1.5 rubles. In this regard, there was a suggestion to use spent drilling cuttings for the construction of non-public roads (field roads). However, the use of drilling mud in its pure form in the construction of roads can lead to undesirable processes of changing the soil of the landscape (waterlogging), to eliminate the effect of waterlogging, it is necessary to mix the sludge with natural soils of sand fractions.

Based on previously developed technologies, it was proposed to use spent drilling mud mixed with local sands in the proportion of sludge: sand from 0.6:1 to 1:1 with a mixture of the resulting technogenic soil directly at the site of laying with a wheel-mounted recycler. After mixing, the soil is compacted with a dirt roller. After the initial compaction, a second pass of the recycler is carried out with the introduction of the resulting cement mixture into the composition. The resulting mixture is subjected to final compaction by analogy with conventional reinforced soils. To reduce the effect of precipitation on the water saturation of the surface layers, it is recommended to treat the surface with a bituminous emulsion or foamed bitumen.

During the construction of the pilot site at the Vostochno-Messoyakhskoye field, a mixture of soil and drilling mud was reinforced with cement or bitumen emulsion using the Wirtgen 2500 double-pass recycler method. The recycling depth of 40 cm (layers of 30 cm of natural soil and 10 cm of drilling mud pre-treated in the barn with cement), followed by the distribution of the binder (cement), leads to the fact that the toxic effect of water solutions of drilling mud is practically not manifested.

It is allowed to use materials obtained from drilling mud with a humidity of not more than 70%. It is possible to use a complex organomineral binder instead of mineral binders. Complex organomineral binder is a rationally selected ratio of organic and inorganic binders that ensure the manufacturability of the production process and the required properties of the construction soil.

Bituminous road emulsions are used as organic binders for the preparation of construction soil according to GOST R 58952.1-2020 [5] with a specially selected component composition, as well as bitumen according to GOST 22245-90 [6] or GOST 33133 [7] in foamed form. Cements according to GOST 30515 [8] and fly ash according to GOST 25818 [9] in an amount of no more than 20% are used as mineral binders for the preparation of construction soil. In terms of compressive strength, cement of a class not lower than 32.5 (grades not lower than 400) is used. The fly ash used must have a specific surface area of at least 300 m2/kg.

According to the preliminary results, a report is submitted to the Customer.

References

1. The Ministry of Energy of the Russian Federation. 2019 Fuel and Energy Complex of Russia. Functioning and development. Moscow, 2020 -156 p.2. URL:http://gazoilexpert.ru/wp-content/uploads/2020/09/Map-of-oil-and-gas-fields-in-Russia.jpg (accessed 03.02.2021).

3. RD 51-1-96. Instructions for environmental protection in the construction of wells on land in the fields of hydrocarbons of a multicomponent composition, including hydrogen sulfide (approved by the Ministry of Fuel and Energy of Russia 25.01.96, the Ministry of Natural Resources of Russia 10.08.96) URL: http://www.consultant.ru/document/cons_doc_LAW_256301/ (accessed 03.02.2021).

4. Order of Rosprirodnadzor of 22.05.2017 No. 242 (ed. of 02.11.2018) "On approval of the Federal Classification Catalog of Waste". URL: https://rg.ru/2017/06/14/rosprirodnadzor-prikaz242-site-dok.html, (accessed 02.02.2021).

5. GOST R 58952.1-2020 Public automobile roads. Road bitumen emulsions. Technical Requirements. Moscow: Standartinform, 2020-12 p.

6. GOST 22245-90 Road oil bitumen, viscous. Technical conditions. Moscow: IPK Publishing House of Standards, 2005-9 p.

7. GOST 33133-2014 Public automobile roads. Oil road bitumen is viscous. Technical requirements (as Amended). Moscow: Standartinform, 2014-12 p.

8. GOST 30515-2013 Cements. General technical conditions. Moscow: Standartinform, 2014-42 p.

9. GOST 25818-2017 Fly ash of thermal power plants for concrete. Technical conditions. Moscow: Standartinform, 2017-24 p.

10. Evaluation report. The main natural and socio-economic consequences of climate change in permafrost areas: forecast based on the synthesis of observations and modeling / Edited by O. A. Anisimov. - OMNNO "Greenpeace Council" - M, 2010: - 44 p.