Introduction.

In modern industrial production in Russia, the practice of integration with foreign companies in the field of supply of components, materials and production technologies is widespread. The destruction of the existing relations has a negative impact on the financial and economic condition of domestic enterprises focused on the use of foreign technologies and equipment. The reduction in output, the suspension of production, and the failure of contracts resulted from the lack of tools and methods for the company’s management to forecast changes in market conditions. In the context of logistic failures and restrictions on supply of tools, spare parts and materials (Slavyanov A.S., 2023), decisions in choosing analogues were made mainly based on their cost and replacement speed, and the consequences of the decision-making for the production process, such as failures, organizational and technical downtime, an increased level of defects and other problems, which caused the loss of financial stability of a number of industrial enterprises (Brizhan A.V., Falko S.G., 2020).

Calculating the consequences of possible options seems to be a very difficult task, which cannot be solved without mathematical modeling and computer programming tools. This circumstance determines the relevance of the problem of building a model of behavior of the production system under external influences.

Materials and Methods

The research was carried out using the methods of system analysis, expert assessments, graphic modeling and computer programming

Results

- The production system model of the enterprise

The financial risks and disruptions in logistics have the greatest impact on product output, enterprises with large-scale and mass production are especially sensitive to these factors (Garnov A.P., Slavyanov A.S., 2024).

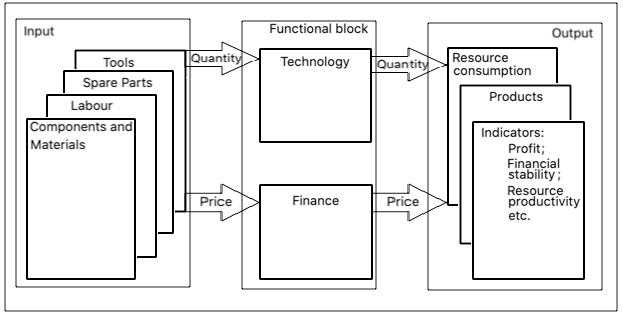

Under these conditions, the production model can be divided into two main blocks: technological and financial, which work with quantitative and cost indicators, and also make it possible to forecast the consequences of decisions made (see Figure 1 for more details).

Figure 1. Structure of the model of the production system of the enterprise

Materials, components, tools in value and physical terms are the input of the model. The volume of production in physical units of measurement (output) and in value terms allows you to calculate the indicators of the enterprise efficiency — the output of the model.

- The technological model of flow production

The technological model of production evaluates the output of products depending on the parameters at the input: changes in the sequence of operations, if it is provided for by the production technology, restrictions on the supply of materials, spare parts, and contains information about the equipment available at the enterprise and its location. The model makes it possible to calculate the number of products produced at the site in the planning period, to assess the need for equipment and workplaces. When building a technological model of a flow production site, an optimal scheme of site organization is prepared, which calculates the location of the equipment taking into account the reduction of costs for movement of labor items. This approach ensures a reduction in the cost of production with the planned production volumes. Optimization of the technological process is achieved by determining the number of workplaces, rational arrangement of equipment and setting the speed of conveyors (Bobkov A.N., Slavyanov A.S., 2023).

Determination of the number of workplaces, transport and warehouse subsystems, arrangement of technological equipment and other specific processes for production ensure the output of products with minimal resource costs.

In the resulting model, it is possible to analyze the consequences of such factors (risks) as a delay in deliveries and subsequent replacement of tools, spare parts for the repair and maintenance of equipment, as well as materials and components of the product. The consequences of replacing original tools and labor items with analogues are shown in Table 2.

Table 2

Threats and consequences of external influences on the production system

| Main Components of the Model | Risks | Implications in the Technological Model | |

| 1 | Tools & Process equipment | Slowing down the processing speed | Overloading at workplaces |

| The quality of the workpiece decreases

Manufacturing defects |

Output is decreasing | ||

| Increased wear and possible equipment breakdown | Increased repair and maintenance time | ||

| 2 | Materials and components for production | Increased operational time | Overloading at workplaces |

| The quality of the product decreases | Change in technology, increase in the duration of operations | ||

| 3 | Spare parts and materials for equipment repair | Slowing down processing speed | Increased operational time |

| The time for setting up and adjusting equipment increases | The time for organizational breaks increases | ||

| Increased repair and maintenance time | The actual fund of working time decreases | ||

| Processing accuracy and product quality are reduced | Output decreases | ||

| 4 | Main production workers and purchasing department employees | Slowing down processing speed | Increased operational time |

| The time for organizational breaks increases | |||

| Labor shortage | Additional costs for the search of personnel | ||

| Increased time to find new suppliers/substitute materials | Output is decreasing in the planned period |

The technology process is greatly influenced by the tool that provides the required quality, and replacing it with analogues can slow down the machining process and reduce the productivity of the entire production line. Replacement of spare parts and materials can have a similar impact, and violation of the equipment maintenance regulations can lead to a decrease in its operating parameters, and frequent shutdowns.

Any change in technology, means of production and supply can result in downtime and disruption of planned tasks.

Thus, it can be concluded that the technological model makes it possible to assess the susceptibility of the production system to various factors.

- The financial model of the production system

In today’s volatile environment, there is a need for a financial and economic model capable of responding to changes in the external environment in the process of creating new value (Badikov G.A., Falko S.G., 2022). Among the main tasks of this model are the processes of short-term planning, as well as collection and processing of actual data in the context of centers of responsibility (CR), for various accounting objects and areas of activity. This will allow you to monitor the financial and economic situation at the enterprise and assess more accurately the impact of external factors on the results of its work.

To assess the impact of various factors in monetary terms, the financial block is focused on preparing information for decision-making, choosing from available alternatives. For these purposes, primary accounting data are used, grouped in the context of management objects — Centers of Responsibility (CR), products.

Division by Centers of Responsibility allows you to control the costs of a workshop, a production site or a machine (Osipov S.V., Khmyrova E.A., 2012). Time accounting in the context of workplace/workshop shows the impact on the cost of manufactured products and downtime due to repairs and disruption of supply chains management, but it is still based on the financial model of the production process.

The data of the technological model of production are put into the information system (computer program) in the form of flow charts and specifications, which can take into account equipment downtime, technological losses of production, the impact of a by-product on the cost of production of the main one, production options, etc., where the financial model is already maintained. This makes it possible to analyze the cause-and-effect relationships between various economic indicators, as well as the consequences of changes in the external and internal environment of the enterprise, such as an increase in prices and tariffs, bank rates, exchange rates, reduction of inventories, etc.

By changing the input parameter, for example, the cost of material or exchange rates, management can make forecasts with a high degree of reliability and assess the possible consequences of the decisions made (Slavyanov A.S., 2016).

When replacing one element with another, the program will take into account the change in costs and recalculate the cost of production, on the basis of which the management can choose the suitable, in its opinion, solution to the problem.

Conclusion

The study made it possible to identify the influence of previously unaccounted indirect factors on the course of the production process. The model implements the function of information support for the decision-making process on the choice of options for the response of the production system to external influences.

Integration of the technological and financial models of the enterprise makes it possible to promptly and objectively inform the management of the enterprise about the possible consequences of making a particular decision at a given time. In addition, the developed model allows you to assess the sensitivity of production to various risks of both external and internal environment. In the future, this model of the production system can be supplemented with elements of artificial intellect, which will significantly expand its capabilities in the field of decision-making in enterprise management.

The approaches proposed by the authors can be used for further improvement and development of the management system, which will contribute to improving the quality of decisions made.

References

1. Badikov G.A., Falko S.G. Economic modeling of costs for the launch of a space system. 2022. T. 1. № 2 (2). Pp. 65-73.2. Bobkov A.N., Slavyanov A.S. Features of the organization of the production process and instrumental economy in the conditions of instability. 2023. № 7(101). Pp. 15-19.

3. Brizhan A.V., Falko S.G. Controlling of Operational Risks in the Electric Grid Company. 2020. № 3 (77). Pp. 40-45.

4. Vaikok M. A. Ponyatie proizvodstvennoy sistemy promyshlennogo predpriyatiya im etapy ee razvitiya [The concept of the production system of an industrial enterprise im stages of its development]. 2016, №40-2. pp. 105-117

5. Garnov A.P., Slavyanov A.S. Problema formirovaniya novoy proizvodstvennoy sistemy v usloviyakh vneshnekh ogranicheniya [The problem of forming a new production system in the conditions of external restrictions]. 2024. № 1. pp. 93-99

6. Grishanov G.M., Kobenko A.V., Klentak A.S. Organization of the rhythmic-cyclic sequence of product release in the conditions of flow production / In the collection: Management of large systems (UBS'2016). Materials of the XIII All-Russian School-Conference of Young Scientists. Under the general editorship of Novikov D.A., Zaskanov V.G.; V.A. Trapeznikov Institute of Control Sciences of the Russian Academy of Sciences; Samara University. 2016. P. 590-598.

7. Osipov S. V., Khmyrova E. A. "The Role of Objects of the Information System of Controlling in Determining the Cost of Educational Programs at the University", Journal of Legal and Economic Research, 2012,3: 147-151

8. Slavyanov A.S. Approaches to the assessment of damage from downtime caused by failures in logistic chains. 2023. № 1 (35). pp. 58-64.

9. Slavyanov A. S. Virtual model of the enterprise on the 1C platform in the conditions of financial instability // In the book: Strategic planning and development of enterprises. Proceedings of the Seventeenth All-Russian Symposium. Edited by G.B. Kleiner. 2016. P. 155-157

10. Leon, Alexis. Enterprise Resource Planning. — 2nd. — New Dehli: McGraw-Hill, 2008. — С. 224. — 500 с