To date, no quantitative analysis of the waste generated at the sites of pulp and paper mills has been carried out, in general, only a small percentage of wood is used for the production of pulp and paper. The rest is disposed of as solid and liquid waste. Moreover, there is almost no trend towards recycling waste into valuable materials in developing countries.

The application of energy-saving technologies is a priority as countries progress towards sustainable development. Recently, the global problem has been to eliminate factors that hinder environmental sustainability, such as climate change, depletion of natural resources, prevention of ecosystem destruction and environmental degradation [1, 2]. Waste from pulp and paper mills strongly affects these factors, therefore, in order to preserve favorable environmental conditions, it is necessary to develop and implement in production energy-saving technologies. Waste water from the pulp and paper industry (CBP) is generated from several sources, such as washing of untreated wood before and after cooking, bleaching of pulp, and, finally, a chemical regeneration system. Solid waste is formed mainly after debarking of wood, due to defects during sorting, primary and secondary sewage sludge, as well as lime sludge from the chemical regeneration system [3]. Currently, pulp and paper mills produce large amounts of solid and liquid waste, and environmental aspects are becoming a serious problem that needs to be addressed.

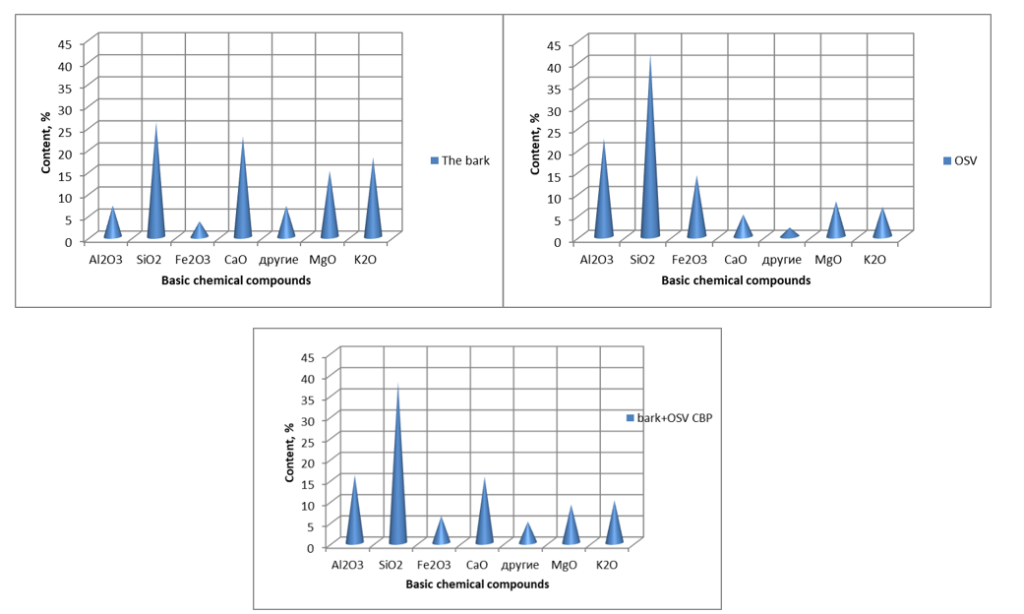

From an environmental and socio-economic point of view, it is extremely important to use appropriate technologies to process waste from pulp and paper mills into high-value products that will affect everyday life. This requires careful quantitative and qualitative analysis of the resulting biomass. This paper considers only a part of the current issues related to the use of waste generated in the pulp and paper industry, namely ash and slag wastm an environmental and socio-economic point of view, it is extremely important to use appropriate technologies to process waste from pulp and paper mills into high-valuts that will affect everyday life. This requires careful quantitative and qualitative analysis of the resulting biomass. This paper considers only a part of the current issues related to the use of waste generated in the pulp and paper industry, namely ash and slag waste. In addit ash (Fig. 1).

Fig. 1. Average comparative chemical composition of ash from waste incineration: 1 – bark; 2 – sewage sludge; 3 – bark + sewage sludge

Ash from the combustion of sewage sludge mixed with wood waste can be used at the enterprise as an alternative coagulant-flocculant (CCF) for wastewater treatment in the industry. The use of specially prepared ash as a reagent is due to the content of aluminum compounds (694 mg/dm3), silicon (909 mg/dm3), iron (80 mg/dm3) and other elements with coagulating properties.

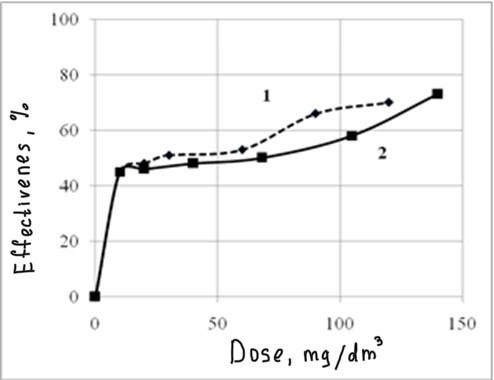

According to the results of the study, the coagulating ability of the ash coagulant depends on the process conditions and the dose of the reagent. As an example, Figure 2 shows the dependence of the efficiency of water purification at the stage of water treatment for production in comparison with the traditional commercial coagulant (aluminum sulfate).

Fig. 2. Dependence of the effectiveness of reducing the color of natural water using various reagents on the dose of active aluminum in their composition at pH =6.2 ± 0.2. Reagents used: 1 – ZKKF; 2 – Al2(SO4)3

According to the data obtained, the cleaning efficiency when using two types of coagulants is commensurate, however, the advantage of ash coagulant-flocculant is that it is a secondary product and it is most advisable to use it directly at enterprises of the pulp and paper industry, where it is formed, thereby solving the problem of closed nature management [4].

In addition, consumers of this prepared product, as an alternative to traditional reagents, may be utilities that use physico-chemical water treatment processes of various origins.

It has been established that the ash in its chemical composition, as a rule, contains compounds such as SiO2, CaO, MgO, Al2O3 and Fe2O3 in different amounts depending on the nature of the materials being burned (Fig. 1). The potential mineral content in the ash after burning precipitation can contribute to the formation of spatial structures that give strength to cement. Therefore, a promising area of use of high-quality concrete is the production of concrete in accordance with the requirements of GOST 31108-2020 «General construction cements» as a mineral component [5, 6]. However, it must be borne in mind that different ashes from the combustion of various types of waste can be used as a mineral component, which may require significant adjustments to create an original composition of the cement mixture. Based on the literature data and experimental studies, the table provides generalized information on the composition of the mineral part of the ash from the incineration of waste from CBP enterprises.

The use of ash in the construction industry solves several problems at once – the disposal of a large amount of accumulated ash in ash dumps throughout Russia and reducing the cost of the final product. A positive technological effect is achieved by maintaining the strength and shrinkage of the cement-concrete mixture when adding ash and slag, which allows them to be introduced into modern cement production technologies.

Thus, the potential use of fly ash as a secondary raw material in industrial wastewater treatment technology and in the production of building materials and cement products is a promising direction in solving waste disposal problems, and also requires a more detailed study of the composition compositions for targeted use.

References

1. Haile, A., Gelebo, G.G., Tesfaye, T. et al. Pulp and paper mill wastes: utilizations and prospects for high value-added biomaterials. Bioresour. Bioprocess. 8, 35 (2021). https://doi.org/10.1186/s40643-021-00385-3.2. Lipsky V.A. Prospects for the development of the timber industry. The need to change the vector of industrial development. Part II // Bulletin of the LESTECH Association No. 15, 2024. Electronic resource. URL: https://alestech.ru/bulletin/article/161. Accessed 10.06.2024.

3. Information and technical handbook on the best available technologies. Pulp and paper production. ITS 1-2023. 459 p. The date of introduction is 2024-01-01.

4. Patent of the Russian Federation 2656305 C2. Method of obtaining a low-concentration composite coagulant-flocculant based on nepheline-containing raw materials and ash / A.B. Dyagileva, A.I. Smirnova, D.V. Dyagileva; patent holder: A.B. Dyagileva. Announced on 29.09.2016; published on 04.06.2018, Bul. No. 16. 8 p.

5. Dyagileva A.B., Smirnova A.I. Comparative characteristics of potential raw materials from biofuel combustion and pulp and paper production waste for the cement industry //Cement and its application. 2024. No. 2. pp. 66-69. DOI: 10.61907/CIA.2024.15.53.001.

6. Shumilova L. V., Khatkova A. N., Razmakhnin K. K., Nomokonova T. G. Application of the best available technologies to improve environmental safety in the disposal of ash and slag waste // Bulletin of Zabaikalsky State University. 2022. Vol. 28, No. 8. pp. 23-34. DOI: 10.21209/2227-9245- 2022-28-8-23-34.