1.Introduction

Plastic is one of the most sought–after materials on our planet. No wonder they say that once there was the Stone Age, then the Bronze Age, and now the plastic Age. 160,000 plastic bags are used every second in the world. Prolonged decomposition of such polymer materials leads to environmental pollution, which has already become a global problem. Scientists find plastic waste at the bottom of the Mariana Trench or in remote areas at the South Pole. Plastic needs to be recycled, for this there are several ways of processing: mechanical, thermal, chemical and radiation. There are also innovative ways, for example, recycling plastic with the help of insect larvae of beetles of the species zofobos morio, which are able to feed on styrofoam. But to all of the above, it should be added that not all types of plastic are recyclable. Polyvinyl chloride materials belong to this category, they are marked with the number 3, and they are usually used to make window frames, food or medicine packages. As well as materials labeled «7», consisting of mixed plastics and packaging materials without labeling at all. But despite such a large number of recycling methods, the Garbage Island still plows the expanses of the Pacific Ocean. According to statistics, 300 million tons of plastic waste are generated per year, which is identical to the weight of half the population of our entire planet, and only a fifth of this mass is recycled, a quarter is incinerated, and half ends up in landfills. Millions of birds and mammals die from plastic every year, and we feed on microplastics without noticing it, which ends up on our table along with fish.

After analyzing all possible ways to solve this problem, we can conclude that the most promising way is to partially switch to biodegradable packaging materials. Biodegradable materials are materials based on plant or natural components, for example, starch, chitosan, polylactide. Such materials are capable of decomposing under the influence of water, sunlight of microorganisms to safe components: the same water, carbon dioxide, or safe organic compounds.

The article will focus on our development – double-layer polysaccharide-based films for food packaging. The film was obtained by casting.

- Materials and methods

2.1 Materials

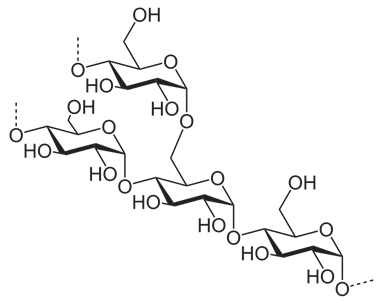

Starch is a plant polysaccharide with a complex structure. It consists of amylose and amylopectin; their ratio varies in different starches (amylose 13-30%; amylopectin 70-85%) [1].

The structural formula of starch is as follows:

Starch

Starch-based materials have great potential as biodegradable food packaging that will reduce environmental pollution. It should be noted that starch has low cost, complete biodegradation, high biocompatibility and good film-forming properties. The functional characteristics of starch-based biodegradable materials can be improved and expanded not only by introducing other biopolymers or additives into the film, but also by using new production methods. However, the large-scale, cost-effective production of starch-based biodegradable materials remains a challenging task, and more research is still needed in this area.

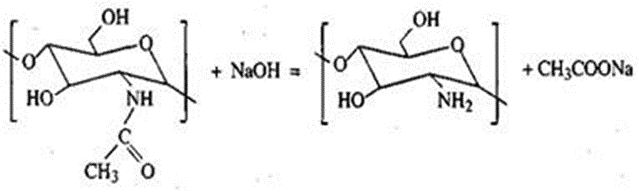

Chitosan is a high–molecular polymer of glucosamine, soluble in dilute inorganic and organic acids (except sulfuric acid). It is a modification of chitin. Chitosan, unlike practically insoluble chitin, which is soluble in acidic solutions, has great potential for use in various industries.

Chitosan production is based on the cleavage reaction of the acetyl group (deacetylation) from the structural unit of chitin-N-acetyl-D-glucosamine [2]:

Chitin Chitosan

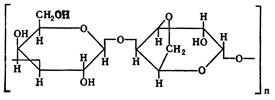

Recently, there has been increased interest in seaweed-based biopolymers and their use in food packaging. Among the various alternatives, agar-agar is an edible biopolymer based on red algae, well known for creating films and coatings for food packaging. The structural formula of agar-agar has the following form:

Agar-agar

There are many processes for extracting agar-agar from seaweed. The innate properties of agar-agar make it a suitable raw material for forming the basic matrix of edible packaging materials. Bioactive ingredients included in agar-agar-based packaging films demonstrate promising potential in active and intelligent food packaging [3]. Biodegradable packaging materials based on agar-agar are prepared using a solvent (water) and plasticizers (glycerin or sorbitol). The finished packaging is transparent and flexible – one of the most important qualities that a film for food packaging should possess [4]. One of the main advantages of biodegradable agar-agar-based packaging materials is safety and minimal environmental impact due to their natural and renewable composition, which is easily compostable or biodegradable, making them a much more environmentally friendly choice for packaging [5]. Biodegradable packaging materials based on agar-agar have many advantages. Firstly, according to safety regulators, such materials are completely safe for food packaging. Therefore, this means that biodegradable agar-agar-based food packaging materials can be used to package a wide range of food products, including cheeses, lactic acid products, and meat. And if the necessary indicator is introduced, the films can be given the properties of signaling consumers about the suitability of the product for ingestion [6]. Biodegradable agar-agar-based food packaging materials can be adapted to meet the specific needs of the consumer. Thus, the film thickness can be optimized to provide greater protection for delicate foods, and the shape and size can be adapted to meet specific packaging requirements. Due to their flexibility, biodegradable agar-agar-based packaging materials can also be used in medicine. However, like everything else in this world, agar-agar-based films also have disadvantages. For example, agar-agar-based films are most often brittle and have poor barrier and mechanical properties [7].

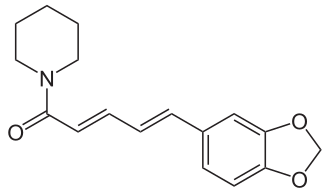

Piperine, the most abundant and potent pungent nitrogen-containing alkaloid in P. nigrum, owes its widespread use to the perfect combination of flavor and health benefits, contributing significantly to its commercial, economic, and medicinal value.

Piperine

Due to its diverse biological activities including anti-inflammatory, anti-cancer, anti-oxidant, and anti-depressant properties, piperine has found extensive applications in medicine and pesticides. Moreover, it is also utilized in food as a supplement where it is often combined with other ingredients to enhance bioavailability. Piperine is a yellow crystalline substance with a melting point of 129 °C and a molecular weight of 285.34 g/mol. It exhibits poor solubility in water (ranging from 40 to 18 μg/mL at 14 °C), but dissolves well in organic solutions such as ethanol (1 g/15 mL) and chloroform (1 g/1.7 mL), while being slightly soluble in diethyl ether (1 g/36 mL). The stability of piperine remains unaffected by acidic environments, however under alkaline conditions it undergoes hydrolysis forming hexahydropyrimidine and piperic acid which are less stable. The photodegradation of piperine occurred, resulting in the formation of isopiperine and isochavicine, as a consequence of its light sensitivity. Moreover, there was a positive correlation observed between the degradation rate of piperine and the intensity of light exposure.

2.2 Synthesis of biodegradable films

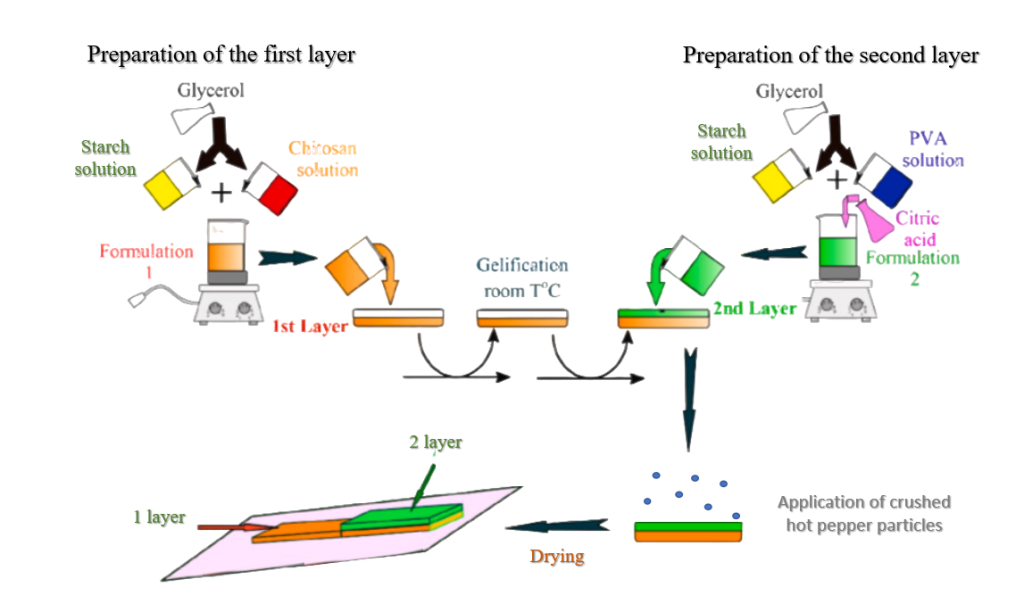

The casting method was used to produce the films. The synthesis scheme is shown in Figure 1.

Figure 1. Scheme of synthesis of biodegradable films

The first layer is the inner one, which consists of starch and polyvinyl alcohol modified with citric acid. Citric acid acted not only as a crosslinking agent to create strong bonds between polymers, but also served as an antioxidant that increased the shelf life of food. After the inner layer was made and solidified for two hours, the second layer, the outer layer, was already applied to it. It was made from a mixture of chitosan and starch, also crosslinked with citric acid. Chitosan was not chosen as the outer layer by chance. The chitosan film is structurally much stronger than the starch film. However, the starch mixture:chitosan forms a flexible and durable film upon solidification. In addition, chitosan acts as a barrier against UV radiation. At the end of the preparation of the outer layer, piperine pepper extract was added to provide a protective barrier for rodents and other pests.

2.2 Biodegradability of analyzed film samples

The biodegradability of the film was studied by immersion in soil. Garden soil was filled into two glass containers to a height of 5 cm. Film samples were prepared by obtaining 2×2 cm squares. The squares were weighed and buried in the soil to a depth of 2 cm. The container with the test samples was stored at ambient temperature (22 ± 2 ° C). Soil moisture was maintained by spraying once a day. The decomposition of the samples was recorded at regular intervals (20, 40, 60, 80 days), carefully removing the film samples and removing the adhering soil with filter paper, followed by determining the mass of the cleaned samples. The weight of the samples should decrease over time. Visual observations were recorded by a camera [8].

- Results and Discussion

Two parallel studies were conducted on the biodegradability of the obtained samples in soil and in compost. Seven test samples were placed in two glass containers – with soil and with compost. Humidity was maintained by spraying once a day. The decomposition of the samples was recorded at regular intervals (20, 40, 60, 80 days), As a result of the study, it was found that all samples of synthesized films completely decomposed in the compost in 40 days. It was not possible to accurately estimate the mass loss of the samples over time, since by the 20th day of burial all the films had decomposed into very small pieces. The degradation of the samples in the soil turned out to be slower than in the compost. As a result of the experiment, it was possible to record the masses of the samples. After 20 days, the mass of the films decreased by about 1.5 times, and after another 20 days — by 3 times. The mass of the films could not be fixed after 60 days, as the samples broke up into very small pieces.

Thanks to the study, it was possible to establish that the films are capable of destruction both in compost and in the soil. This can be explained by the fact that the resulting packaging materials are biodegradable macromolecular polymers of a hydrophilic nature, so soil and compost moisture can easily penetrate the polymer network, weakening polymer chains and hydrolyzing by soil microorganisms. The destruction of films in the soil is slower than in compost. This can be explained by the difference in microorganisms. To establish the period of complete decomposition of films in the soil, it is necessary to continue observations.

The article discusses a method for producing biodegradable double-layer films. The method of artificial decomposition in the soil has proved that our films really decompose both in the soil and in the compost. In addition, an innovative modification of the films is being considered. In the future, it is planned to conduct a study of the alleged barrier properties against rodents and pests.

References

1. Food chemistry / Nechaev A.N., In S. Rauber.Family., And Kochetkov.A. not others. Land rent. boiler. A.Very. Nechaev. – St. Petersburg: Giorom of this, 2001. – 592 P.;2. Chitin and chitosan: Preparation, properties and application / Edited by K.G. Scriabin, G.A. Vikhoreva, V.P. Varlamov. – M.: Nauka, 2002. – 368 p.;

3. Roy, S. Agar-based edible films and food packaging application: A

comprehensive review / Roy, S., Chawla, R., Santhosh, R., Thakur, R., Sarkar, P., Zhang, W. // Trends in Food Science & Technology. – 2022. – Vol. 141. – Article 104198;

4. Mоstаfаvi, F. S. Agаr-bаsеd еdible films for fооd packaging applications-A review // International Journal of Biological Macromolecules. – 2022. – Vol. 159. – Р. 1165–1176;

5. Bоsе, I. A. Comprehensive Review on Significance and Аdvancements of аntimicrobial аgents in biodegradablе fооd packaging/ Bоsе, I., Rоy, S., Pаndеy, V., & Singh, R. // Antibiotics. – 2022. – Vоl. 12(6). – Аrticle 968;

6. Dоrа, T. R. K. Synthesis and evaluation of physical prоpеrtiеs of Agar biopolymеr film cоating—an alternative for food packaging industry / Dоrа, T. R. K., Ghоsh, S., Dаmоdаr, R. // Materials Research Express. – 2024. – Vol. 7(9). – Аrticle 095307;

7. Rоy, S. Starch/agar-based functional films integrated with еnоki mushroom-mediated silver nanoparticles for active packaging applications // Fооd Biоsciеncе. – 2022. – Vol. 49. – Article 101867;

8. Orsuwan, A., Shankar, S., Wang, L.F., Sothornvit, R., Rhim, J.W. Preparation of antimicrobial agar/banana powder blend films reinforced with silver nanoparticles // Food Hydrocolloids. V. 60. 2016. P. 476–485.