Nowadays, more and more measuring devices, sensors, cameras, communication means and data storage systems are becoming available to obtain information about the situation in the city. Energy and engineering facilities are no exception. The task of increasing the efficiency of resource consumption, reducing the negative impact on the environment determines the need for operational monitoring of the situation at housing and utilities facilities, keeping accurate records of energy consumption, real-time control, in particular, on hot water supply pipelines.

The quality of pipe integrity control has a great influence on ensuring trouble-free and economical operation of heating pipelines. Among various options for solving this problem there is the idea of introducing systems of remote control of pipelines condition. Such a system consists of hardware and software solutions. One of the hardware solutions for functioning of remote monitoring systems is proposed to modernise heat chambers of the heating network, where sensors and devices necessary for remote monitoring will be installed.

To ensure safe operation of pipelines it is necessary to promptly obtain information on the technical condition of pipelines and parameters of the product pumped through them (temperature, pressure, flow rate, etc.). Various defects occur in pipeline systems during their operation. Table 1 shows the ratio of the number of defects depending on their cause.

Table 1

Distribution of the number of detected defects depending on the cause of defect occurrence [1]

| Cause of the defect | Number of defects detected | Percentage of defects detected |

| Fistula | 2586 | 21% |

| Corrosion | 5487 | 45% |

| Valve malfunction | 1468 | 12% |

| Weld seam | 220 | 2% |

| Other | 2348 | 20% |

| TOTAL: | 12109 | 100% |

Based on the defects detected, the main cause of pipeline damage is corrosion processes. The damage caused by corrosion is 45%. In most cases, external corrosion is localised, covering no more than 30-40% of the pipe perimeter. In ducts and chambers corrosion of the upper part of the pipe occurs as a result of intensive dripping from the slab, and the lower part — as a result of waterlogging and contact with the ground.

The causes of such damages in heat chambers are: low quality of applied insulating materials, poor-quality sealing of pipelines passage through the wall of heat chambers, which results in waterlogging and flooding of heat chambers.

And intensive development of external corrosion of pipelines of heat networks is explained by the following factors [2]:

— weak protective properties of insulation used in previous years;

— high groundwater level in St. Petersburg;

— unfavourable temperature and humidity conditions of operation in partitions; structures, conditions of

— presence of harmful influence of accompanying and crossing heat network communications;

— incomplete coverage of the heat network pipelines by means of electrochemical protection.

Corrosion leads to thinning of the walls, which violates the overall strength of the pipeline and because of this cracks, fistulas and fractures are formed [3]. Through such damages, hot water starts to leak and this process can develop either quickly or slowly, but in any case leads to an emergency situation. Figure 1 shows a pipeline defect — a breach of pipe thermal insulation.

Figure 1. Disturbance of the thermal insulation of the pipeline

The causes of such defect are:

— poor quality of welds at pipe joints;

— localised ulcerative corrosion of internal surfaces due to metal defects and violations of water and chemical regime;

— breach of tightness of coupling joints and insulation end caps with corrosive and aggressive moisture penetration to the outer surface of pipes;

— poor adhesion and delamination of the thermal insulation layer from the pipe surface with formation of voids where moisture can accumulate.

These defects do not lead to accidents, but reduce energy efficiency, as part of the heat is not used for its intended purpose, but goes outside, which, in turn, leads to significant economic losses.

Currently, leaks are diagnosed in a simple but unreliable way. Copper conductors are laid along the entire pipeline. After a few hundred metres, carpets are placed on the ground parallel to the location of the pipeline, with the ends of the conductors attached to terminals. When a leak occurs, the resistance of the conductors changes and this is how you can find out about the accident and the approximate distance to it. This method is not reliable, as the conductors may not short-circuit immediately after the leak occurs because the leak may start on the opposite side of the pipe from the laying of the conductors. Also, a conductor closure may occur without a leak.

In order to carry out the pipeline inspection procedure, quite a large number of resources need to be deployed [4]. In order to assess a pipeline section, a team of at least five people is required. It is necessary to disconnect the pipeline section, to drain the pipeline surface and to remove the thermal insulation. The human factor that can affect the measurement and inspection of a pipeline should not be overlooked. It is possible to obtain incorrect data due to various errors in the use of the measuring device or disturbance of the measurement process due to insufficient qualification of the employee.

At the moment, the project «Creation of a digital analogue of heat network pipeline systems» is being developed, which will allow to receive operational information on the condition of pipelines in the city.

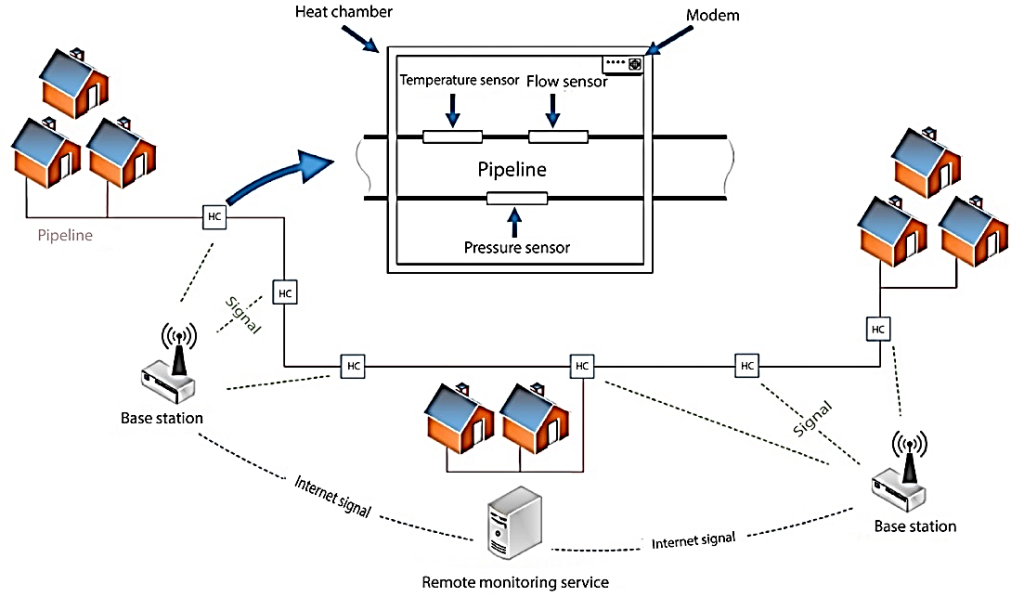

Figure 2. Schematic of remote modelling of heat pipelines

Sensors and monitoring devices planned to be installed in the heat chamber and connected to the modem will collect information about the state of the pipeline (Fig. 2). The technology of energy-efficient LoRaWAN (Low-power Wide-area Network) [5] has been chosen to build the information transmission network.LoRaWAN network is a radio network. Communication between the terminal devices and the server is carried out through radio signal repeaters, which are Vega BS-1.2 or Vega BS-2.2 base stations.

The main information about the state of the heat pipeline is obtained in the heat chamber — a buried reinforced concrete structure with flanged pipe connections, fittings for placing and maintaining joints, gate valves and other heat pipeline equipment (Fig. 3).

Figure 3. Heat chamber

Based on the experience of operation of heating pipelines in the housing and utilities sector, a list of parameters was determined, the values of which will be used for predicting emergency situations and assessing energy efficiency: the pressure and flow rate of water in the pipeline can be used to judge about water leakage in the section, the temperature of water can be used to judge about the condition of thermal insulation in the section.

When selecting sensors for measuring the above parameters, the following requirements were taken into account:

— compliance of the range and accuracy of measurements with the measured parameters;

— possibility of electrical connection of sensor outputs with the inputs of wireless data transmission devices (radio modems);

— possibility of sensor operation both at high humidity and in hot water (in case of flooding of heat chambers);

— possibility of sensor operation in a given range of temperatures typical for a given area;

— low power consumption, taking into account the absence of mains power supply in heat chambers.

The quality and accident-free operation of pipeline systems is of particular importance for any city. Heat network piping systems are the backbone of the system for supplying the population, production and agriculture with one of the vital products such as hot water. To ensure reliable and economical operation of heat pipelines, a remote monitoring system is being developed.

Remote monitoring system is a hardware-software complex, which allows to provide round-the-clock remote collection and analysis of data on the condition of the pipeline.

The software for real-time monitoring of the heating network is designed to monitor the condition of the heating network by downloading converted and moved reports with readings of temperature, pressure, coolant flow rate, residual battery charge, unauthorised access, recording incoming information in the database and generating reports.

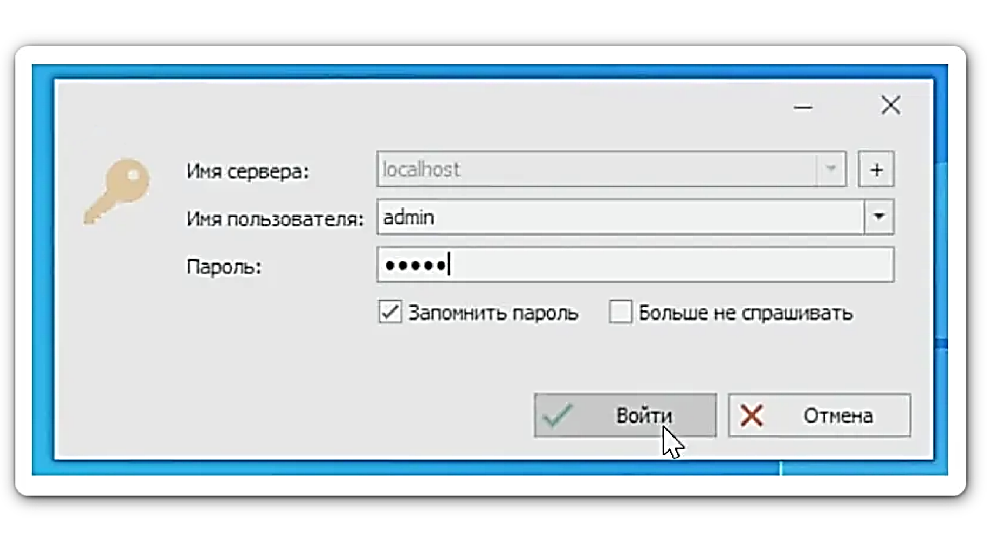

The program is a special software that requires logins and passwords to enter to exclude unauthorised intervention (Fig. 4).

Figure 4. Interface of the main form of the programme

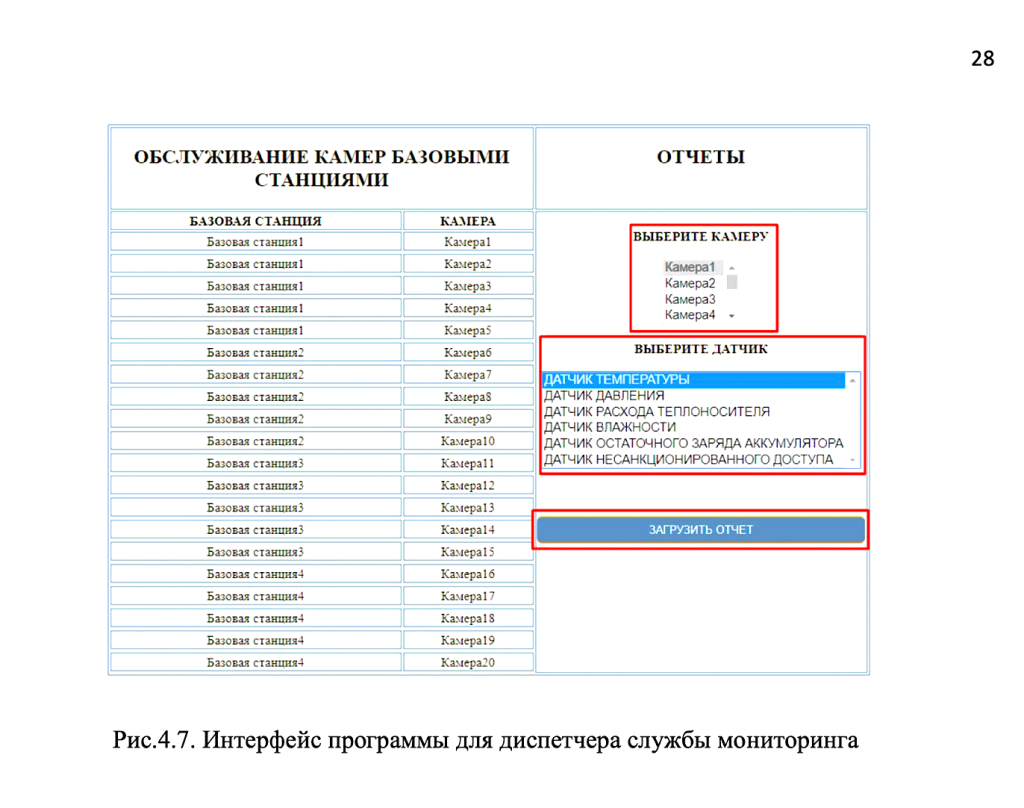

Access to the user programme becomes possible after registration confirmation by the monitoring service administrator. The programme enables the monitoring service dispatcher to upload reports to the remote server IOT Vega Pulse (рис. 5) [6].

Figure 5. Programme interface for the monitoring service dispatcher

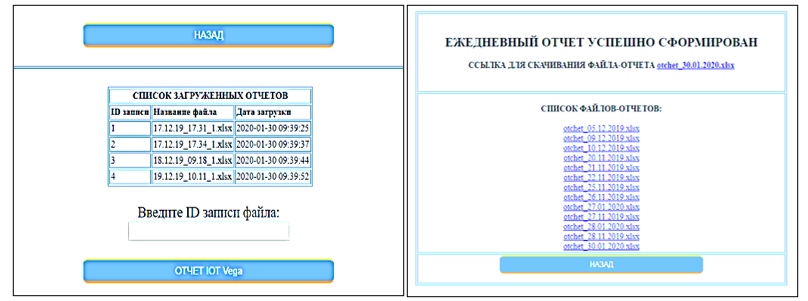

The programme allows the administrator of the monitoring service to add the data of the files uploaded to the server to the tables of sensor readings (Fig. 6a), as well as to generate reports on the remote server in the form of files of format MS Excel (Fig. 6b).

a b

Figure 6. Programme interface:

a — for the administrator of the monitoring service

b — for report generation

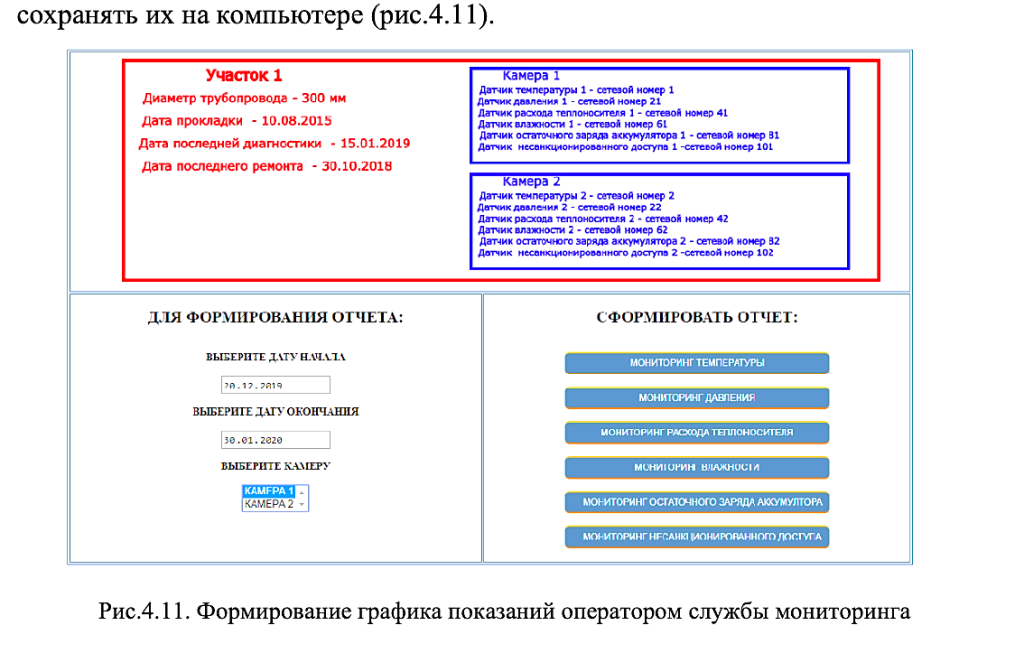

The monitoring service analyst can save daily report files on the computer, generate and save reports for a selected period for a selected sensor on the computer. These files can be used for further analysis in the sensor signal processing software. Thanks to the programme, the monitoring service operators generate graphs of readings of sensors installed in the heating network chambers and save them on the computer (Fig. 7).

Figure 7. Generation of a schedule of readings by the monitoring service operator

The remote monitoring system enables optimisation of heat supply management processes. The analysis of data on energy consumption and equipment operation allows to identify potential bottlenecks in the system and optimise its operation to improve efficiency and save resources, as well as enables 24/7 remote collection and analysis of data on pipeline condition. A notable aspect of the remote monitoring system after implementation is the increased comfort level for end users. Thanks to more reliable and efficient heat supply management, it is possible to ensure stable and high-quality provision of heat supply services, which has a positive impact on the level of comfort and customer satisfaction.

Installation of the unit design with sensors and devices for remote monitoring will allow to qualitatively modernise heat chambers and ensure efficient operation of the system. Thanks to remote access to data, operators can quickly identify the location and cause of the problem, which reduces response time and minimises losses.

References

1. Shiryaev, A. D. Increasing the efficiency of heat supply systems: problems and solutions / A. D. Shiryaev // International Journal of Professional Science. - 2023. - № 7. - С. 75-82. - EDN QEJTVN.2. Gladyshev, N. N. Efficiency of regulation of heat energy supply to the heating systems of residential buildings / N. N. Gladyshev, A. D. Shiryaev, O. A. Dolzhenko // Energy, control and automation: innovative solutions to problems : Proceedings of the II All-Russian Scientific and Practical Conference of students and teachers, St. Petersburg, December 22, 2022 - SPb: VShTE SPbGUPTD, 2023. - С. 78-81. - EDN KHIDUE.

3. Astashov, A. S. Main factors influencing the occurrence of corrosion of heat network pipelines laid underground / A. S. Astashov // Experimental and theoretical research in modern science: Collection of articles on the materials of the XIII International Scientific and Practical Conference. Vol. 4 (13) : Association of researchers "Siberian Academic Book", 2018. - С. 32-35.

4. Bolotov, S. V. System of operational remote control of the condition of polyurethane foam insulation of heat network pipelines with digital moisture sensors / S. V. Bolotov, N. V. Gerasimenko // Bulletin of the Belarusian-Russian University. - 2016. - № 2(51). - С. 139-147.

5. LoRaWAN specification. Introduction. Basic concepts and classes of terminal devices - [Electronic resource] - URL: https://habr.com/ru/post/316954/ (Accessed 19.02.2024).

6. IOT Vega Pulse - [Internet resource] - URL: https://vega-absolute.ru/production/telemetriya/iot-vega-pulse/ (Accessed 3.03.24)