Introduction

With the global intensification of industrial development and the restructuring of production systems, the development of methods for optimizing production processes is becoming increasingly relevant. Modern industrial enterprises are faced with the need to respond promptly to the evolving state of the technological conditions and global competition, and this requires the introduction of new approaches to making operations more effective. Of particular interest is the implementation of sophisticated technological solutions aimed at rationalizing each stage of the process of production.

The goal of the current research is to analyze production process optimization technologies applied in foreign practices. The study is focused on the definition of the dominant characteristics and requirements for effective use of automation technologies, robotization, and lean technologies.

Achievement of this goal will create the possibility for comparative analysis of optimization techniques, identification of general trends and features of national strategies. It will help to increase production streams and implement innovative methodological solutions with the ability to ensure stable growth in the efficiency of industrial business under the conditions of a dynamically developing world economy.

Main part. Methods for improving the efficiency of production processes

Contemporary companies are faced with the need to constantly upgrade their production chains in an effort to competitively at the international level. Of key significance among areas of interest is taking up integrated technological solutions to maximize each step of the production chain. With regard to this, extra emphasis is placed on the integration of sophisticated digital technology, monitoring and control systems to curb time costs and reduce errors in production. With the assistance of advanced sensors, programmable logic controllers, and applications software, not only is the effective coordination of individual production process stages feasible but also real-time monitoring with the assistance of which there is a significant reduction in energy costs and improving the quality of products. For example, research has demonstrated [1] that companies employ digital twin technologies to allow them to replicate physical items and manufacturing lines as virtual representations so that they can perform various simulations in real time. They aim to reduce equipment downtime by 20 to 30 %.

Another very important area is the use of robotization of production which greatly redesigns traditional methods of carrying out operations in production. Modern robotic complexes perform a huge set of operations-from fixing parts to performing welding operations and packing finished products. High precision and flexibility of robot control allow you to reduce the cost of operations, and increase the level of product quality by eliminating the influence of the human factor. The use of robot lines ensures a significant reduction in equipment downtime, and this has a beneficial impact on the performance of operations. For example, analytical examination of a number of businesses has shown that the use of robots can lead to a significant improvement in productivity and a reduction in the cost of production by 10% to 30% [2]. This, along with labor safety enhancement by mechanizing hazardous work, is a crucial element of a universal production efficiency increase.

With the installation of digital and robotic technologies, special attention is given to the use of lean technology – a lean production system aimed at the structured elimination of losses and optimization of all phases of the production process. The above method in Lean requires continuous observation of current processes, the creation of bottlenecks and implementation of measures to their elimination, leading to the overall system’s efficiency improvement and cost reduction of production [3]. Implementation of lean manufacturing principles, such as reduction of equipment changeover times and optimal internal process logistics, reduces production losses, improves product quality and maximizes staff performance. Therefore, the combined use of these techniques is the most significant foundation for attaining sustainable success in the optimization of production processes.

Comparative characteristics of optimization strategies

A comparative examination of production process optimization strategies illustrates the necessary contrasts in methodology applied across different regions, and general tendencies determined by current technological developments. Modern production environment is based on digital transformation with the implementation of solutions in automation, robotics, and lean manufacturing (table 1).

Table 1

Comparative analysis of optimization strategies by region

| Region | Optimization strategies | Key technologies | Expected results |

| North America | Centralized digitalization, management modules. | Artificial intelligence (AI), automation | Increased overall production efficiency and reduction of operational costs. |

| European Union | Implementation of digital twins, predictive maintenance. | Digital twins, Internet of Things (IoT) | Reduction of equipment downtime, improvement in service quality. |

| Japan and South Korea | Integration of robotics with predictive maintenance. | Robotics, AI | Improved accuracy and stability of processes, reduction of unexpected failures. |

| China | Lean technologies and digital transformation. | Digital systems, Lean | Process optimization, reduction of waste, and improvement in product quality. |

| India | Production modernization, IoT and AI implementation. | IoT, AI, Big Data | Faster decision-making, increased operational transparency. |

Global industry is characterized by variability in approaches to optimization of production processes, according to the level of economics, traditions and state support of innovations [4]. In the comparison of the strategies used in a range of countries, there are distinctions according to the level of infrastructure development, investment possibilities and strategic priority of the region.

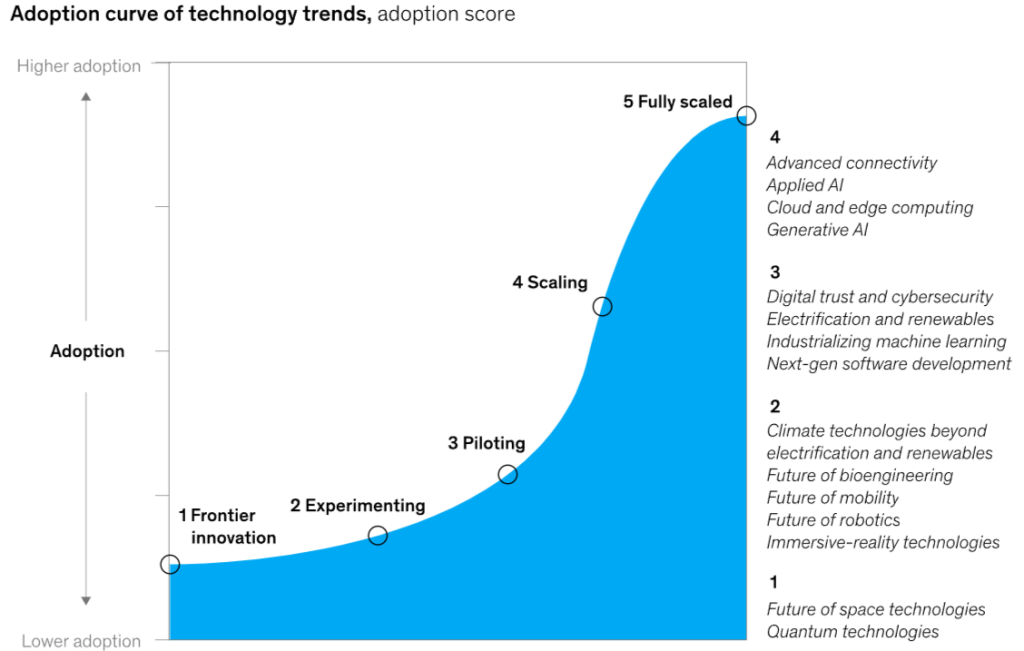

For example, in America, cutting-edge investment and rapid technology solution uptake are predominant approaches. For optimization in such an instance, success will critically depend on the ability to accelerate innovations fast by way of flexible and adaptable systems of management. The American business approach allows you to reduce the cost of production and increase efficiency, owing to close integration of robotized production lines and the ability to quickly adapt business processes in a highly volatile environment. It is accompanied by constant modernization of the technology park and real use of data, which makes the American approach distinct from traditional approaches in other markets [5]. In general, in global practice, as the 2024 McKinsey study shows, certain technologies are more developed and receive greater investment, while others lag significantly behind (fig. 1).

Figure 1. Implementation curve of technological trends, implementation assessment [6]

Examples of American companies successfully utilizing advanced technologies for optimizing production and sales include Tesla and Amazon. Tesla actively implements robotic production lines and AI to automate processes, reducing production costs and increasing the efficiency of electric vehicle assembly. Amazon, in turn, applies machine learning algorithms and robotics in its warehouses, ensuring high-speed order processing and adaptive logistics in response to market fluctuations. This approach reflects the characteristic American strategy of rapid modernization and business process flexibility, distinguishing it from traditional management methods in other countries.

In the Western European countries, special emphasis is put on the overall digitalization of production systems, where the intensive use of digital twins and analytical platforms reduces the total proportion and provides more accurate forecasting of maintenance. This is achieved through the deep integration of information technologies into traditional production processes, which establishes a solid foundation for the digitalization of business. For example, the German company Siemens actively utilizes digital twin technology in manufacturing, enabling predictive maintenance and optimizing production efficiency, thereby reducing costs and downtime.

In Asia, there are relatively distinct optimization strategies. For example, Japan employs the creation of robot systems, as a result of which it can achieve higher sustainability of production processes by accurately placing robots in production lines. South Korea and China employ a combination of lean optimization and digital transformation, as a result of which they can achieve shorter production cycle times. It is remarkable that state and private sector investment projects have a significant influence in these countries, which allows creating favorable conditions for the realization of innovations and modernization of production processes. This integrated approach results in sustainable productivity growth and operational risk reduction [7]. For example, Toyota in Japan integrates robotic automation with the Kaizen philosophy, ensuring continuous improvement and efficiency in production while maintaining sustainability. Similarly, Samsung in South Korea combines lean manufacturing principles with AI-driven analytics to optimize supply chains and reduce production cycle times, enabling faster adaptation to market demands.

An analysis of optimization strategies shows that the success of optimization is determined not only by technological innovations, but also by the degree of adaptation of organizational structures, corporate culture, and readiness for change. As a result, a comparative analysis of different countries highlights the importance of a systematic approach to optimization, when technological modernization is combined with a competent management policy.

Evaluating the effectiveness of optimization strategies

Assessing the impact of optimization strategies requires a comprehensive approach that incorporates various quantitative and qualitative tools. These methods help measure how the implementation of technological and organizational innovations contributes to the enhancement of production system performance. The evaluation is based on multi-criteria models that allow us to examine both short-term and long-term consequences, for example, the cost-effectiveness of investing in optimization programs. The main focus is on indicators such as the return-on-investment ratio, the reduction in production cycle length, and the decrease in unscheduled equipment shutdowns, allowing efficiency to be divided into financial and operational components.

The efficiency evaluation method is based on the application of new analytical platforms and mathematical modeling, by means of which you can compare system performance before and after the optimization measures are implemented. At the same time, it is particularly important to research key success indicators, identify the change dynamics of production processes, and calculate the difference between planned and actual results [8]. For example, applying sensitivity analysis and regression models, it can be established that slight increases in each process element will guarantee productivity growth. Execution of these processes allows you to create scenarios of further development of optimization measures, to adjust management and customize quality control systems in real time.

Among the most important components of this appraisal is constructing straightforward scenarios based on which it is possible to determine the influence of introducing new technologies. The developed models make it possible to calculate the monetary effects of optimization, for example, reducing equipment maintenance costs and reducing the rate of unplanned shutdowns and hence directly influencing overall production profitability. Companies use precise KPI that include payback periods and operational stability indicators, which allows us to state with confidence that the efficient use of innovations leads to significant improvement in the performance of main indicators. Such quantitative data allows managers to make reasonable decisions on further optimization project development and technology scaling implemented.

Thus, evaluation of optimization policy effectiveness is a continuous process of monitoring, modeling and adapting implemented changes, which ensures high flexibility of production systems for a dynamic market condition. The received information as a result of such auto-regulated analysis can not only reduce the cost of operation, but also ensure sustainable growth of production capacity and improve the company’s competitive position.

Conclusion

As a result of the comparative analysis of optimization techniques for production processes, it is possible to conclude that the successful implementation of modern technologies, such as digital twins, robotics and lean technologies, is defined not only by the level of technological maturity, but also by the character of organizational structure and management styles in different countries. Regional differences, such as the possibility of quick scaling of innovation, the level of government support and investment opportunities, play a key role in determining winning strategies. At the same time, the flexibility of optimization approaches, such as automation and predictive maintenance via data, speaks volumes about their immense potential in cost reduction and productivity improvement. Hence, in order to achieve long-term outcomes in the optimization of production processes, both technological and organizational factors need to be taken into account, which can significantly contribute to the competitiveness of companies in the global economy.

References

1. Digital twins: The next frontier of factory optimization / McKinsey & Company // URL: https://www.mckinsey.com/capabilities/operations/our-insights/digital-twins-the-next-frontier-of-factory-optimization (date of application: 03.03.2025)2. Revolutionizing Manufacturing: How Robots Boost Productivity, Quality, and Safety / The ROBOT REPORT // URL: https://www.therobotreport.com/revolutionizing-manufacturing-how-robots-boost-productivity-quality-and-safety (date of application: 03.03.2025)

3. Debnath B., Shakur S., Bari M., Karmaker L. A Bayesian Best–Worst approach for assessing the critical success factors in sustainable lean manufacturing. // Decision Analytics Journal. 2023. Vol. 6. P.100157. DOI: 10.1016/j.dajour.2022.100157 EDN: XYNVKK

4. Malikov A. Adaptive scaling strategies: methods and approaches of startups for entering international markets // Polish journal of science. 2024. № 81. P. 20-23. DOI: 10.5281/zenodo.14546236 EDN: MKHFIC

5. Selimov A. Legal aspects of international corporate transactions in globalization contexts // International Research Journal of Modernization in Engineering Technology and Science. 2024. Vol. 6(11). P. 6051-6054.

6. McKinsey Technology Trends Outlook 2024 / McKinsey & Company // URL: https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/the-top-trends-in-tech (date of application: 03.03.2025)

7. Chaisse J., Hsieh L. Rethinking Asia-Pacific regionalism and new economic agreements. // Asia pacific Law review. 2023. Vol. 31. № 2. P.451-468. DOI: 10.1080/10192557.2023.2216056 EDN: MXSQFQ

8. Sahoo S., Lo C. Y. Smart manufacturing powered by recent technological advancements: A review //Journal of Manufacturing Systems. 2022. Vol. 64. P. 236-250.