According to Henrik's theory, there are statistics that for every 300 dangerous incidents, there are 29 minor injuries and 1 fatality. However, a total of 3,321 dangerous incidents were recorded in Mongolia from 2016 to 2024, of which 509 employees lost their lives and 761 employees suffered serious injuries. If we simply calculate the statistical figures from Henrik's theory, there are 11 deaths and 73 injuries for every 300 dangerous incidents in our country.

- INTRODUCTION

Objective: To introduce an occupational health and safety management system in the manufacturing sector.

Materials and Methods: An analysis of laws, legal acts, standards, and research materials in force in Mongolia was conducted.

In the development of Mongolia, the position of high-risk sectors such as mining, construction, and energy has increased, and their social responsibility, risks, injuries, and dangerous incidents have begun to attract widespread attention from citizens to the head of state. In this day and age, the processing industry is also a sector that deserves attention.

The Government of Mongolia, in collaboration with the Ministry of Food, Agriculture and Light Industry and the Food and Agriculture Organization of the United Nations, has been implementing good occupational safety and health practices in the processing industry, mainly in the leather, wool and cashmere processing sector, since March 2018. As a result, projects and programs are being implemented to protect workers from potential accidents and create opportunities for the production of value-added final products from livestock-based raw materials and export them in accordance with international standards. In this sector, where there is a lack of professional training for OHS specialists, it is commendable that the establishment of an OHS branch committee under the Ministry of Food, Agriculture and Light Industry will continue to plan and implement OHS issues in the leather, wool and cashmere processing industry at the policy level.

Because.

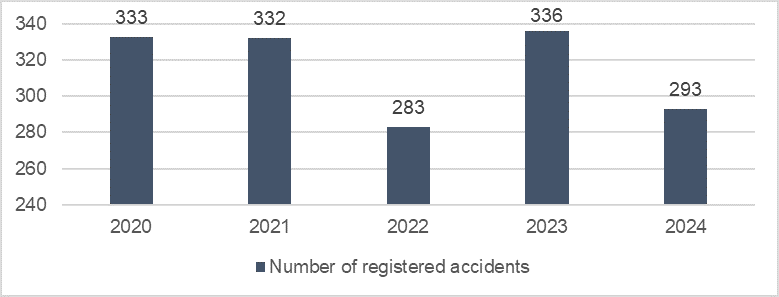

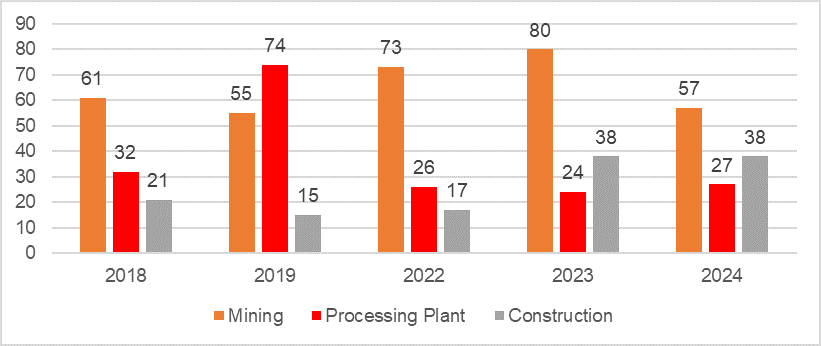

Although industrial accidents and acute poisoning are more common in the mining and construction sectors, the number of accidents in processing plants has begun to attract attention in recent years. As large mining companies and enterprises pay more attention to occupational safety, industrial accidents are relatively decreasing. The accident rate in 2024 decreased by 39 cases compared to the previous 4 years, and by 70 cases in 2018-2023. Also, 3,078 new cases of occupational diseases were diagnosed between 2006-2013 and 425 cases in 2014-2022, indicating the effective implementation of the HEMAB management system in the sector.

However, the number of accidents in the manufacturing sector is on the rise. In Mongolia, a total of 120 industrial accidents and acute poisonings have been recorded in the manufacturing sector over the past 3 years, resulting in 9 deaths.

- THEORETICAL OVERVIEW

Occupational Health and Safety

Every organization has a responsibility to ensure the occupational health and safety of its employees and all participants in its activities. Some legal documents state that this responsibility includes activities to protect and promote the physical and mental health of employees. For example::

- It refers to comprehensive risk protection activities aimed at maintaining human working capacity and health and creating healthy and safe conditions during work. / Law on OHS/

- Being healthy means not only physical health issues, but also the perfect state of mental and social health. / WHO Declaration/

Ensuring occupational health and safety within the legal framework is a pressing issue today.

Today, enterprises in Mongolia comply with legal documents such as 8 laws, nearly 200 standards, orders, decisions, rules, regulations, and instructions of the Minister of Labor and Social Security and sector ministers regarding OHS.

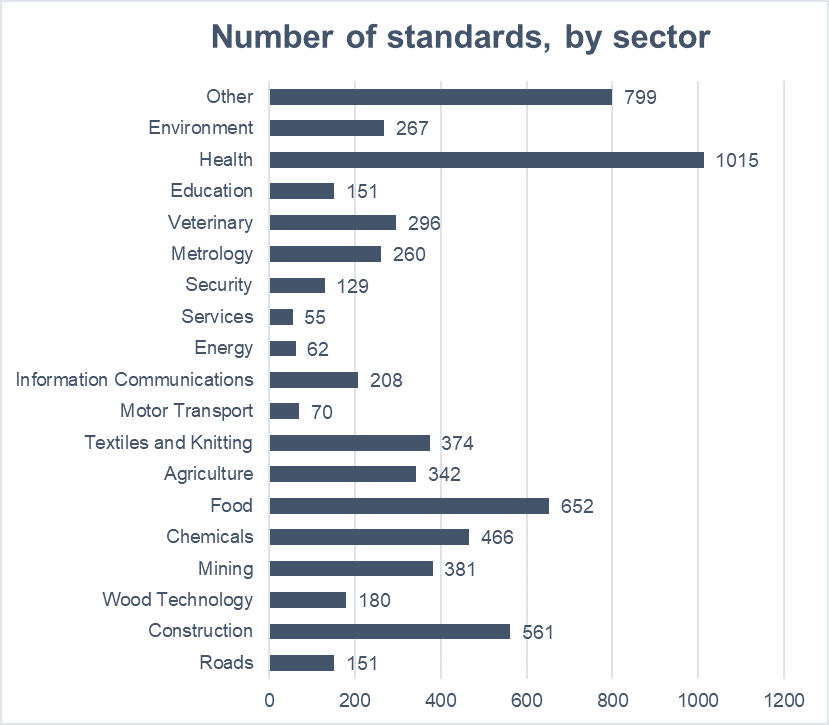

Source: Mongolia with Standards Program

Figure 1: Standards in force in Mongolia

There are a total of 5853 standards in Mongolia, and when comparing the data with the standards implemented in other countries, the following results were obtained. These include:

- Internationally recognized ISO 23010 standard

- China has 180,000 standards

- Germany has 30,000 standards

- Russia has 35,000 standards

- Mongolia has 5,853 standards, which shows a lack of product, service and operational control in our country.

Standards and Quality and Safety

International trade agreements are being concluded because the quality and safety of products and services supplied to the markets of developed countries around the world is determined by the system of standards, technical regulations, conformity assessment, and control mechanisms related to the product. Today, ISO standards are used as the primary criteria in more than 160 countries around the world.

According to the study, only 31.3% of our country’s MNS standards comply with ISO standards.

Table 1

National Standard Level Quantitative Indicators

| National standard level | ||

| MNS | 4022 | 1831 or 31.3% is consistent with many national and regional standards. |

| MNS ISO | 1163 | |

| MNS EN | 45 | |

| MNS CAC | 102 | |

| MNS ASTM | 133 | |

| MNS AASHTO | 71 | |

| MNS IEC | 90 | |

| Other | 228 | |

| Total 5853 | ||

Source: Mongolia with Standards Program

The OHS situation in Mongolian manufacturing is characterized by high risks, weak management systems, and a lack of a safety culture.

Although international projects, ISO standards, and government training measures have been introduced in recent years, systematic implementation at the small and medium-sized enterprise level is still insufficient, and employees’ safe working environments are still not fully protected.

III. RESEARCH SECTION

Mongolian processing industries are rich in raw materials, but weak domestic processing capabilities, technology, financing, and market penetration hinder the production of high-value-added products; the solution lies in policies focused on cluster/sector support, infrastructure improvement, standardization, and training of specialists. According to the results of the World Bank study, Mongolia’s economic growth is largely dependent on mining. Mongolia’s economic growth is largely driven by mining and related consumption and investment, which has not provided a consistent and independent boost to the growth of manufacturing.

Manufacturing accounts for a relatively small share of total domestic production, and exports are mostly in the form of primary raw materials. In recent years, research reports have highlighted the dominance of manufacturing, including animal products and food, leather, textiles, light manufacturing transactions, and low-value-added exports.

The following are common barriers to the development of processing industries in Mongolia. These include: technical and technological backwardness, lack of investment (secure financing), skills/expertise shortages, logistics/energy costs/burdens, environmental and regulatory issues, and safety policies. These hinder the ability of factories to expand, import substitution, and absorb high export costs.

SMEs are key players, but growth has been slow. This is because these organizations are often small, have outdated technology, and have limited market information and guarantees, which slows development. Despite government support and policies, studies have noted that implementation and the institutional environment need to be improved.

The leather, textile, and meat/food processing industries have high export potential and sufficient raw material resources, but lack quality, technical configuration, and marketing for medium/high-end production (advanced leather processing, market-oriented branding, and standardization). In this regard, the UNDP leather research emphasizes the sector’s infrastructure and value-added capacity.

Industrial Competitiveness Analysis (UNIDO) — common conclusion: export products are often low-tech, export diversification is low, and innovation and FDI activities are lacking, so competitiveness needs to be increased.

The number of enterprises and organizations operating in the manufacturing sector is shown in Figure 2.

By sub-sector as of 2024

Source: Industry Survey

Figure 2: Enterprise Survey

As of 2024, there were 187.1 thousand registered business entities operating in our country, of which 8,000 or 8.5 percent were operating in the industrial sector. 78.7 percent of the businesses operating in the industrial sector were operating in the manufacturing sectoProcessing plantr.

Number of industrial accidents registered in Mongolia

Source: Researcher’s elaboration

Figure 3: Accident survey /national level/

Number of industrial accidents

An industrial accident is considered to be an injury or death to an employee due to exposure to production factors during the performance of their duties.

Source: Researcher’s elaboration

Figure 4: Accident statistics /by sector/

In our country, the mining, construction, and energy sectors are currently considered to be the most risky. Based on the industrial accident statistics recorded in the manufacturing sector nationwide, it can be seen that workplace occupational health and safety (OHS) in this sector is one of the most important issues.

Total manufacturing production

The total production of the industrial sector reached 30.1 trillion tugriks in 2024, with the mining and quarrying sector accounting for 57.5 percent of the total production, and the processing industry accounting for 32.8 percent. The processing industry accounted for 24.9 percent of the total production in 2015, which increased by 7.9 percentage points to 32.8 percent in 2024, indicating that the production of this sector is likely to continue to grow.

- Total manufacturing activity by sector:

- Food production: 51.3%

- Leather, leather products, textiles, and clothing production 10.4%

- Other other manufacturing 38.3%

Introduction of the HEMAB management system in the processing industry

There are 3 organizations accredited and certified by the National Accreditation Body of Mongolia according to the MNS ISO 17021 standard, and those organizations have the right to conduct certification according to the management system standard throughout Mongolia within the scope of their accreditation. Also, since 2016, foreign certification bodies have begun to conduct certification activities through enterprises operating in Mongolia. To date, there are very few registered enterprises that have been certified by national and foreign accreditation bodies through the introduction of the HEMAB system.

ISO standards are voluntary, meaning that businesses and organizations choose to implement them. Our country’s policy is to support the increase in exports of value-added final products from the manufacturing sector, which makes it necessary to introduce and implement this standard in the sector.

Status of Implementation of Occupational Health and Safety Management System Standards in Mongolia

General situation of OSH in the processing industry. The processing industry (leather, food, construction materials, textiles, wood processing, etc.) is considered one of the sectors with the highest risk of accidents and occupational diseases. According to the 2023 “Occupational Safety Report” of the National Labor Organization, about 30-35% of all occupational accidents occur in the processing industry.

The most risky sub-sectors are:

- Leather and wool processing (chemical exposure, respiratory exposure)

- Food and meat processing (cuts, slips, cold exposure)

- Wood and building materials production (dust exposure, heavy equipment accidents)

The main OHS risks in the processing industry can be summarized as follows:

- Weak OH&S management system

- There is no formal OH&S management, standards and regulations at the SME level.

- OH&S training, risk assessment and internal control are inconsistent.

- Very few factories have implemented international safety standards such as ISO 45001.

- Chemical and biological risks

- Although chemicals such as chromium, sulfur and formaldehyde are widely used in leather and wool industries, there is a lack of protective equipment and inadequate ventilation.

- Some studies indicate that 40–60% of workers do not regularly use protective clothing, gloves and masks.

- Occupational diseases

- Respiratory, hearing, and skin diseases caused by chemical exposure, dust, and noise are common.

- There is a lack of health screening, monitoring, and information — many factories do not conduct annual health screenings for employees.

- Weak supervision in local industrial zones

- There is a shortage of inspectors from the General Directorate of Occupational Safety and Health at the aimag and soum levels, small factories operate at the “garage level,” and accident records are lacking.

- Even when safety violations are detected, fines are low and accountability is weak.

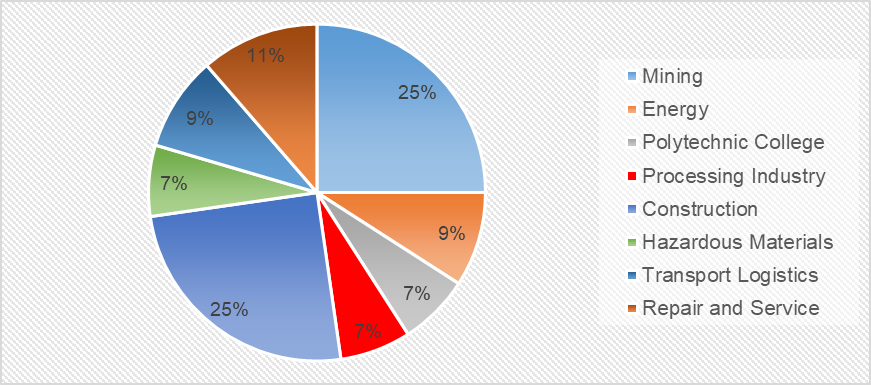

The enterprises that have implemented the OHSMS management system standards are shown in Figure 6, categorized by field of activity. These organizations have been certified by the following professional organizations. These include:

- 11 organizations certified by the Australia-New Zealand Accreditation Authority

- 25 organizations of the nationally accredited “SFCS” LLC

- 6 organizations of “Moncertf” LLC

- 3 organizations certified by the French “Afnor” group

Source: Researcher’s elaboration

Figure 6: Certified Organization Survey

When interviewing management, supervisory staff, and managers at all levels of the organization, they say that «Safety» is important. However, when asked about the work you and your organization are doing to ensure safety, they say that our organization and sector are less risky than industries such as mining, construction, and energy, so they give instructions and warnings saying «Ensure your safety.»

If we look at the problem more closely, the system of the high-risk sector itself has created a foundation for mandatory compliance with safety.

Accidents and deaths do not come suddenly. This is not a concept that nothing can be done, but a concept that every business entity, organization, and employee should systematically and continuously do a good job in performing their work.

Table 2

Summary of the OHS situation in the processing plant (as of 2024)

| Indicator | Condition / Research Results | Key Issues | Directions for Improvement |

| 1. General OHS management | 70–80% of SMEs do not have a formal OHS program | Weak regulatory oversight and management system | Phased introduction of ISO 45001, MNS 5002:2016 standards |

| 2. Occupational accident rate | ~30–35% of all occupational accidents occur in processing plants | Violation of safety regulations, weak equipment protection | Regularization of safety training and risk assessment |

| 3. Chemical use | Chromium, sulfur, and formaldehyde are widely used in leather and wool industries | Poor ventilation, lack of protective equipment | Implementation of chemical management procedures and MNS standards |

| 4. Use of protective equipment | 40–60% of workers do not regularly use protective clothing and equipment | Lack of OHS culture, weak control | Create a system of incentives and penalties for employers |

| 5. Health surveillance and examination | About 50% of factories do not conduct annual inspections | Lack of health records and information | Introduce an electronic registration system and legalize preventive examinations |

| 6. Occupational diseases | Respiratory, hearing, and skin diseases are common | Dust, noise, chemical exposure | Introduce ventilation and noise reduction technologies |

| 7. Monitoring and enforcement | Insufficient supervision of the State Environmental Protection Agency at the aimag and district levels | Small local industries are out of control | Increase the number of local inspectors, electronic monitoring system |

| 8. OHS training and culture | 60% of employees do not receive regular training | Weak OHS awareness | Implement a combined system of continuous training and monitoring |

| 9. Good practices | Large factories (“Gobi”, “APU”, “Darkhan Leather”) have started implementing ISO 45001 | Limited scope | Dissemination of successful cases, exchange of experiences between sectors |

| 10. International support | ILO, UNIDO, Switch-Asia projects are being implemented | Short duration of projects and low sustainability | Develop policies to integrate project results into the national system |

Source: Researcher’s elaboration

The level of OHS in Mongolian processing industries is high, with weak system controls and a culture of protection not fully developed.

- CONCLUSION

To develop its processing industry, Mongolia needs to pay attention to the following issues:

- Focus on high value-added clusters — focus on deep leather processing, meat/food processing, clean-tech food production, and value-added light industries.

- Improve infrastructure, logistics, and energy security — this will reduce market access costs and increase export competitiveness.

- Implement policies that focus on SME financing, technical assistance, and standardization — export standards, certification, quality control, technology transfer, and human resource development are needed.

- Shift to green and sustainable production — introducing low-waste, energy/water-saving technologies will improve long-term competitiveness.

The ISO 45001:2018 system standard is a concept, guideline, method, and methodology that integrates the best practices of humanity in the past, accepted by more than 160 countries, and a guide to human well-being and happiness. Therefore, we need to introduce and implement it in our activities without distinguishing between high risk and low risk.

In order to supply Mongolian raw materials, products and services to countries around the world, it is important to introduce the OHS management system in the processing industry. Therefore, processing industries need to improve their management and increase the value of educated and healthy workers.

There is a need to integrate OHS into economic sector policies by aligning them with sector development policies, SME support, standardization, and training programs.

References

1. Ann S, L. S. (2015). Methology for creating empirically supported agent based simulation with survey data for studying group behavior of construction workers. Journal of Construction Engineering and Management, 141.2. Charles.Z, K. S. (2017). Understanding Human Behavior and Social Environment. USA: Cengage Learning Inc.

3. Choi B, L. S. (2017). Role of social norms and social identifications in safety behavior of construction workers. Journal of construction engineering and management, 143.

4. Eastman, C. (1910). Work accidents and the law. New York: Survey Associates, Inc.

5. Estacio, P. (2019). Effectiveness of applying a behavior based safety program in industrial modular construction. Leadership in Sustainable Infrastructure. Vancouver, Canada.

6. Fleming, D. D. (2000). Safety culture maturity model. Colegate, Norwich: Her Majesty's Stationery office.

7. Fugas, C. S. (2012). Profiling Safety Behaviors: Exploring of the sociocognitive variables that best discriminate between different behavioral patterns. Risk Analysis 33, 838-850.

8. Geller, S. (2001). Behavior based safety. USA: Cambridge university press.

9. Gravina, N. E. (2019). Training leaders to apply behavioral concepts to improve safety. Safety sceince 112, 66-70.

10. Kines, P. A. (2013). Improving safety in small enterprises throught an integrated safety management intervention. Journal of Safety Research, 87-95.

11. Li Xingwei, H. L. (2019). A Review of Worker Behavior Based Safety Research: Current Trends and Future Prospects. Earth and Environmental Science (хууд. 371). China : IOP Publishing.

12. Lingard, H. R. (1997). Behavior based safety management in Hong Kong's construction industry. Journal of Safety Science, 243-256.

13. Luttans, F. (2005). Organizational Behavior. NY, USA: McGraw-Hill.

14. Marlina Zaira, H. (2017). Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Safety Science, 124-135.

15. National safety council. (1998). Accident facts. Itasca IL.

16. Pompian.M. (2011). Behavioral Finance and Wealth Management. New Jersy: Wiley Finance Publications.

17. Reason.J.P. (1998). Organizational control and safety: The varieties of rule-related behavior. Journal of Occupational and Organizational Psychology, 71(4), 289–304.

18. Robbins, S. P. (2007). Organizational Behavior. Pearson Prentice Hall.

19. Scott Geller, D. J. (1999). Critical success factors for Behavior-based safety. Journal of Safety Research, 237-249.

20. Zohar, D. (1980). Safety climate in industrial organizations. Journal of Applied Psychoology, 96-102.

21. Баатартогтох, Ц. (2012). Нийгмийн шинжлэх ухааны судалгааны арга зүй. Улаанбаатар.

22. Ганчимэг, Г. (2014). Байгууллагын хөгжил, соёл. Улаанбаатар.

23. Гэлэгжамц, С. (2022). Эрдэм шинжилгээ судалгааны арга зүйн хичээлийн гарын авлага. Улаанбаатар: Хөх Монгол принт.

24. Ж.Ганчимэг, Б. Г. (2020). Хөдөлмөрийн аюулгүй байдал, эрүүл ахуй. Эрдэнэт: Мөнх Арвижих Үйлс.

25. https://www.iso.org/home.html

26. http://masm.gov.mn/

27. http://sfcs.mn/

28. https://www.legalinfo.mn/law/details/564

29. http://www.moncertf.mn/index.php?module=content&id=96

30. http://oshmi.mn/?page_id=267

31. http://mscs.mn/

32. http://om.inspection.gov.mn/#/content-category/2?_k=o5id84

33. http://inspection.gov.mn/new/