Today, heat pumps (HPs) occupy an important place in heating systems all over the planet, which provides an efficient and environmentally friendly solution to meet the needs for heat and cold. HP uses millions of installations in various parts of the world, including Japan and Europe, where heat pumps play a key role in ensuring a comfortable climate in residential and commercial buildings.

The variety of types of HPs allows their effective use in various climatic conditions and for a variety of tasks. HP production is closely related to the needs of each country’s domestic market, with large industrial manufacturers in the United States producing hundreds of thousands of pieces of equipment annually. In Germany and other parts of the world, the emphasis is on the development of large thermal pumping plants that provide large areas and facilities with significant capacity and efficiency.

Heating systems based on HP are distinguished by their environmental safety, since their operation is not associated with the combustion of fuel resources and, therefore, is not accompanied by the release of harmful substances into the atmosphere.

These systems are also noted for their high efficiency: investing 1 kW of electricity can lead to the production of 3 to 5 kW of thermal energy, depending on the operating conditions and the selected operating mode. The main advantages of using HPs include reducing initial investments due to the absence of the need for gas connections, improving housing safety by eliminating the risk of a gas explosion [1].

The use of heat within the recycling circuit in systems with heat pumps makes it possible to further increase energy and economic efficiency by integrating cooling, heating and water heating into one system. Such installations are suitable for a wide range of applications from private to pre-industrial construction.

The use of alternative and environmentally friendly energy sources is a key solution to prevent a possible energy crisis. In addition to developing traditional energy resources such as gas and oil, there is great potential in using energy from natural sources such as reservoirs, soil, geothermal sources, as well as technological waste including air, water and wastewater.

The energy generated by the heat pump is extracted from sources with low temperatures, as well as from the additional power required to operate the compressor.

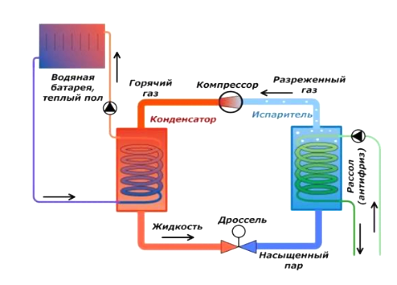

The HP consists of three main circuits: an internal circuit that returns heat to the heating system or three circuits: the building’s hot water supply; an external circuit that evaporates and absorbs heat from the refrigerant before condensation; and a second circuit that uses the refrigerant liquid coolant before condensation (Fig. 1).

Figure 1. The principle of operation of the heat pump

The external circuit is an underground or submerged pipeline that is used to circulate antifreeze. The second circuit, which uses the refrigerant, includes an evaporator and condenser heat exchangers, a compressor and a throttle that controls the refrigerant pressure. The expansion of the compressor causes the pressure of the refrigerant to drop when it reaches the evaporator, where it boils and absorbs heat from the refrigerant to start a duty cycle. The compressor then sucks in the refrigerant gas, compresses it, heats it, and passes it into the condenser. Where it gives off heat to the water in the heating system. After condensation, the refrigerant re-enters the throttle, and the cycle repeats [2].

One of the outstanding features of the heat pump is the possibility of using it for air conditioning in the summer, when the system operates in the opposite direction: heat is taken from the building and transferred back to the ground, water or air.

This technology is gaining popularity due to its ability to provide economical heat supply with minimal environmental impact.

For a 300-square-meter apartment building with effective insulation and a need for hot water for four people, the annual thermal energy requirement is estimated at approximately 50,000 kWh.

When using natural gas for heating, about 8 kWh of thermal energy can be extracted from one cubic meter of gas. Given the efficiency of the gas boiler at 90%, the actual amount of heat generated is reduced to 7.2 kWh per cubic meter. Thus, about 7,000 cubic meters of natural gas per year will be required to meet the specified heat demand.

HP air-water – This type of system extracts energy from the outside air. The heat is then transferred to a refrigerant, usually freon, which begins to boil and turn into steam. Next, the gaseous refrigerant is sent to the compressor, where its pressure and temperature increase. At the end of this process, the freon condenses, giving off heat to the heating system of the house [3].

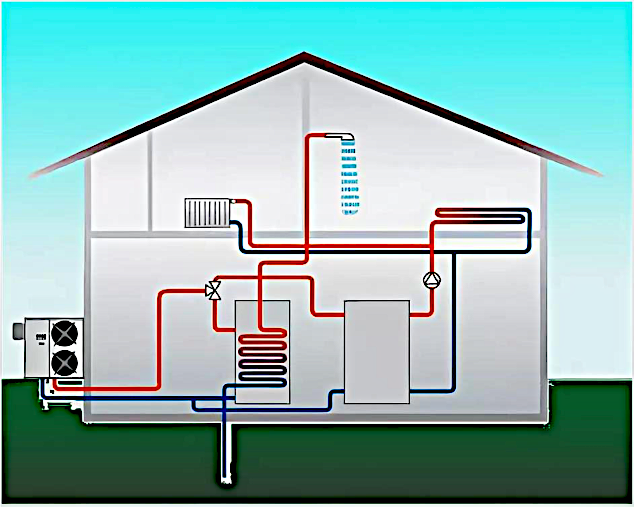

HP air-to-air – operate similarly to air conditioners, but in reverse mode (Fig. 2). These devices capture air from the outside and supply it to a heated room already in a heated state. Guiding channels and ventilation systems are used to ensure uniform distribution of warm air throughout the building.

A special feature of air HPs is their ability to function effectively even at very low outdoor temperatures, up to -25 °C. This means that they can independently provide indoor heating in winter until the air temperature drops below the specified threshold [3]. At lower temperatures, the efficiency of the device decreases, and in regions with particularly cold winters it is recommended to use alternative solutions or additional sources of heating.

Figure 2. Air-to-air heat pump

HP is considered the most productive, which uses energy from the soil, making it possible to completely abandon traditional energy sources such as gas and coal. Even in conditions of severe frosts, it is able to provide reliable heating and hot water supply. This category also includes heat pumps that use groundwater as a source of low-potential energy, which are described in detail in the section on wastewater.

Such geothermal equipment extracts heat directly from the soil. The earth at a depth exceeding the freezing level maintains a stable temperature throughout the year, making it an ideal source of heat. The energy received from the ground is accumulated and transferred further to the evaporator, where the refrigerant, a non-freezing liquid, is heated.

The choice of the collector type depends on the characteristics of the site. Horizontal systems are more economical to install, but require significant space. Vertical systems, in turn, are suitable for areas with a limited area, but their installation is associated with higher costs due to the need for drilling operations.

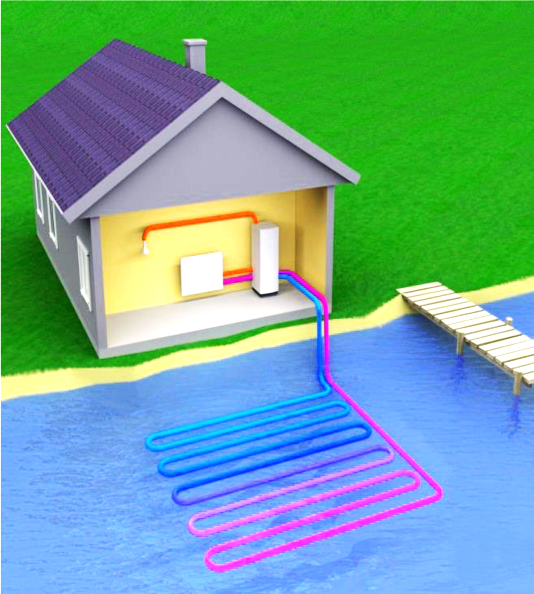

Water-to-water heat pumps use thermal energy contained in groundwater or water bodies directly near the house (Fig. 3). Their attractiveness lies in the stability of groundwater temperature, which ranges from 12-17 °C throughout the year. To access this energy, drilling of a pair of wells for water inlet and outlet is required, while the drilling depth can exceed one hundred meters, which implies significant financial investments [4].

An alternative and more economical option is to install a collector at the bottom of a nearby reservoir, provided it is deep enough to prevent water from freezing in winter. In regions with a cold climate, the depth of the reservoir should be at least three meters, and the water level should remain constant.

The choice of a specific type of heat pump depends on several factors, including the geolocation of the house, the climatic conditions of the area, the proximity of water sources and the availability of sufficient free space on the site, as well as the overall budget and specific requirements for heating and hot water supply of the facility.

Figure 3. Water-to-water heat pump

Heat pumps are classified according to the principle of their operation into compression and absorption pumps. Compression pumps operate using mechanical energy, usually derived from electricity, whereas absorption models can operate from thermal energy, using both electricity and fuel.

Heat pumps are also divided into types depending on the heat source. Among them are:

Geothermal pumps that extract heat from soil, surface, or groundwater. They can be [5]:

- a) Closed type:

Horizontal collectors are laid in horizontal trenches at a depth exceeding the depth of soil freezing (usually more than 1.2 meters). This option is economically advantageous for residential areas where there is enough space to accommodate the contour.

Vertical collectors are placed in wells that can reach up to 200 meters deep. This method is chosen in conditions of limited area or when it is important to keep the landscape unchanged.

Heat pumps can use different sources to extract heat, which divides them into several categories. Water-based geothermal pumps, for example, install winding or ring collectors in reservoirs (lakes, rivers, ponds) at depths exceeding the freezing level. This method is economical, but requires compliance with certain conditions, such as the minimum depth and volume of the reservoir, which vary depending on the region.

Direct heat transfer, in which the refrigerant is transferred through copper tubes installed in different configurations — vertically in wells with a depth of 30 meters and a diameter of 80 mm, at an angle in wells with a length of 15 meters or horizontally in the ground below the freezing depth — is a unique feature of the following type of geothermal pumps. Due to the direct heat exchange between the refrigerant and the ambient air through copper pipes with excellent thermal conductivity, this method provides greater efficiency and reliability. It also reduces the overall length of wells, which minimizes installation costs.

Water acts as a heat carrier in open-cycle systems, where it is sent back to the ground after passing through a heat pump system. This method is limited to areas with an abundance of relatively clean water and no regulatory restrictions on the use of groundwater.

In contrast, air heat pumps extract heat from the surrounding air, making them a versatile choice in many places where there are not many alternative heat sources.

Finally, some heat pumps use other heat sources, such as waste heat from pipes used in industry. This strategy is particularly relevant for industrial facilities with easily accessible and efficiently used sources of parasitic heat.

Depending on the type of coolant that passes between the inlet and outlet circuits, heat pumps can be divided into eight main groups: ground-water, water-water, air-water, ground-air, water-air, air-air, freon-water and freon-air. These devices can also act as heat recuperators, transferring heat from the pumped air to the incoming air. The choice and efficiency of a heat pump is mainly determined by the local climate, especially with regard to systems that use atmospheric air as a heat source. There are millions of such devices operating on the principle of air conditioning in hot regions [6]. Whereas in cold climates they are.

Even at temperatures down to minus 25 degrees Celsius, some versions of the air-to-air and air-to-water systems can operate up to minus 40 degrees Celsius. However, they still have low thermal efficiency, only 1.5 times higher than conventional electric heaters, with an average increase of 2.2 times for each heating season. In conditions of extreme cold, additional heating is often required, since the main power of the fuel pump may be insufficient, which leads to the inclusion of alternative heat sources.

Wells must be drilled at a depth of 100-200 meters to extract heat from rocks. A U-shaped collector made of two plastic pipes filled with a 30% solution of ethyl alcohol supplies antifreeze to these wells. The environment has a big influence on the reaction. Groundwater naturally transfers heat from rocks to the coolant that fills wells. If the well is overloaded or too short, the water and antifreeze may freeze, which will reduce the maximum heat output of the system. For control systems, the temperature of the antifreeze at the return is crucial. A 10 kW heat pump requires a well with a depth of about 170 meters, since it generates an average of 50-60 watts of heat per running meter. Digging several shallow wells is more financially profitable than a single well with a depth of more than 200 meters.

For a small 110-120 square meter house with low energy consumption, the time required to pay off the initial investment is only 10-15 years. In addition, most systems operate during the summer months because they facilitate the movement of heat, which is essentially solar energy, from the interior to either groundwater or rock formations. Granite acts as an essential conductor of heat in mountainous regions such as Scandinavia, effectively storing thermal energy in summer and giving it away at night or in winter. The bowels of the Earth and groundwater are sources of heat. Extracting heat from the ground is one of the most effective methods, despite its significant cost. Since the temperature of the earth at a depth of several meters is constant throughout the year, the effectiveness of this technology does not depend on the weather. By 2013, only 500,000 systems were installed in Sweden, compared with 50,000 in Finland and 70,000 in Norway annually. The installation of antifreeze underground often takes place at a depth of 0.7 to 1.2 meters, 30-50 centimeters below the freezing point of the earth. The heat source for this project comes from the ground. Manufacturers recommend placing collector pipes at a distance of at least 1.2 meters from each other and no more than 1.5 meters. Drilling is not required at this location, but a significant amount of excavation work is required over a vast area.

In addition, the water supply in this area is more susceptible to damage. It does not require additional soil preparation and is just as effective as using a well to extract heat. The ideal location is moist soil; otherwise, a larger circle will be required. In clay, it is estimated that 50-60 watts of heat is generated per meter of pipe; in sand 30-40 watts. These figures are lower in the northern regions in temperate latitudes. As a result, the construction of a 10 kW heat pump requires 400 m2 (20 x 20 m) of land, which requires a ground loop length of 350-450 m. Well-designed contours have little effect on the green environment.

It is advisable to reduce the required depth to 50-70 meters, while increasing the heat output to 700 watts per meter in wells with a larger diameter (218-324 mm).This is achieved by including the active circuit of the main converter of the heat pump in the well. This method is especially effective in wells equipped with submersible pumps and tubeless water lifting systems. These systems generate a stream of water, which actively increases the performance of the main circuit of the converter. As a result, more heat can be extracted not only from the surrounding ground, but also from the circulating liquid.

When using nearby bodies of water as a heat source, the contour should be located at the bottom of the reservoir, making sure that it is at least two meters below the surface. The energy conversion efficiency of a heat pump is comparable to that obtained by extracting energy from the ground. Since a meter of pipe can withstand about 30 watts of heat output, 300 meters of pipeline must be laid in the tank to support a 10 kW heat pump. To avoid buoyancy in the pipeline, a weight of approximately 5 kg is applied to each running meter. Commercial versions can have annual energy consumption in the range of 70 to 80 kilowatt-hours per square meter. To provide heating during severe frosts, when there is not enough heat from the external circuit, a bivalent heating scheme can be used. This means that when the temperature drops below a set threshold (bivalent temperature), an auxiliary heat source is automatically activated, usually a small electric heater, which compensates for the lack of thermal energy.

Since it takes only 0.2–0.35 kWh of electricity to transport 1 kWh of thermal energy to the heating system, heat pumps provide significant energy savings. Compared to traditional power plants, where the efficiency is close to 50%, this significantly improves fuel economy. In addition, the use of closed circuits, which have virtually no operating costs other than energy, can improve fire safety and optimize ventilation systems.

Moreover, fan coils or ceiling cooling systems can be switched from heating mode to cooling mode in summer, connected to an external collector. HPs are easy to use because they are reliable. They work very quietly and are about the same size as a regular refrigerator. Since the system is configured according to the unique requirements of the user, it becomes possible to evaluate the economic efficiency and optimal choice of energy sources.

References

1. Dil, A.D. Features of the use of air heat pumps in the conditions of the Far North / A.D. Dil // Bulletin of the Magistracy. – 2023. – № 11-2(146). – Pp. 41-44.2. Dautov, R. R. Classification of heat pumps used in the heat supply of residential buildings / R. R. Dautov // Tinchurin Readings - 2023 "Energy and digital transformation" : Proceedings of the International Youth Scientific Conference. Kazan: Kazan State Power Engineering University, 2023. pp. 374-377.

3. Khamitova, A.M. Possibilities of using heat pumps in Russia / A.M. Khamitova, A.V. Stavitsky // Agrarian science in the context of time : Proceedings of the LX international scientific and practical conference of students, postgraduates and young scientists – Tyumen: State Agrarian University of the Northern Urals, 2025. – pp. 95-99.

4. Loginova, S. A. Assessment of the prospects for the use of heat pump heating systems for residential buildings / S. A. Loginova, A. A. Timoshin // Engineering and Construction Bulletin of the Caspian Region. – 2022. – № 4(42). – Pp. 22-26.

5. Kondratiev, A. E. The use of a heat pump for heating an individual home / A. E. Kondratiev // Instrumentation and automated electric drive in the fuel and energy complex and housing and communal services : Proceedings of the VII National Scientific and Practical Conference. Kazan: Kazan State Power Engineering University, 2022. pp. 705-707.

6. Ananyin, G. E. Research on the effectiveness and potential of heat pumps / G. E. Ananyin, I. A. Balykov, I. A. Khotko // Digitalization and innovations in agroengineering as a means of increasing the efficiency of the agro-industrial complex : A collection of scientific papers based on the materials of the National Scientific and Practical Conference – Yaroslavl: Yaroslavl State Agrarian University, 2023. – Pp. 7-15.