Introduction

The initial stage of developing new territories begins with creating conditions for comfortable living and safe work. These conditions can be achieved through the construction of a series of shelters that protect workers and equipment from the negative impacts of the external environment, such as solar radiation, high and low temperatures, dust, moisture, etc.

However, constructing such shelters in unfavorable environmental conditions poses high risks for personnel, who will be forced to work on unprepared sites in unfavorable conditions. This circumstance makes the problem of reducing production risks in unfavorable environmental conditions urgent. It is necessary to minimize the use of manual and mechanized labor at protected sites and operations. The use of automated machines and robots [1, 2] in the initial stages of territorial development projects will reduce the time and cost of preparatory work.

Materials and Methods

The objective of this study is to develop a model for constructing automated production lines operating in aggressive natural environments. This goal is achieved through scientific observation, abstraction, and modeling. The theoretical foundation of the study is based on the work of Russian and international scientists in the field of industrial engineering. The information base for the study is based on open publications in scientific journals and the media.

Result

The project for the development of territories and facilities includes the following stages:

- development of a scientific and production base;

- preparation of infrastructure;

- organization of work to achieve project objectives.

The first two stages will require a significant amount of building materials for the construction of the base and infrastructure. The primary materials for the base are building blocks of various shapes and sizes. Building blocks can be imported from the mainland or manufactured from local raw materials. Transporting building materials to hard-to-reach areas can significantly increase the timeframe and cost of the entire project. If the technology for producing blocks from local raw materials is available, mass production of these products can be established near the construction site.

The problem is that organizing the production of building materials will require the involvement of workers and specialists, who will be forced to work in hazardous environmental conditions.

To organize production, it is proposed to use transport and technological modules that form an automated line for the production of building blocks.

Transport robots are self-propelled platforms equipped with manipulators for handling loads. Currently, there are many different types of transport robots that can be used in the technological process.

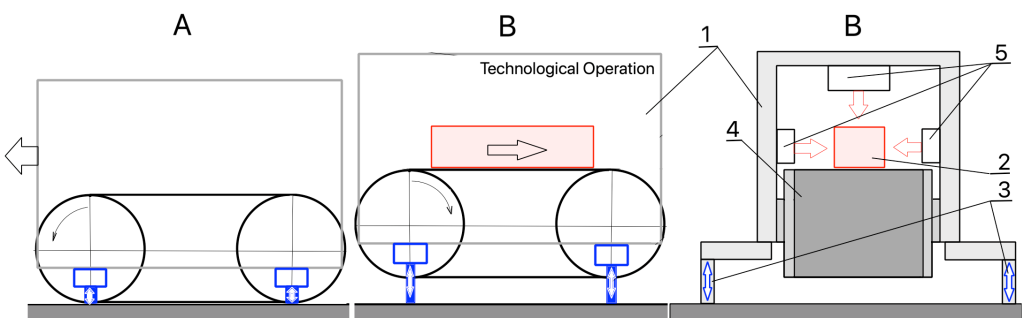

What is new is the design of the technological module, which is a set of equipment for changing the shape or state of an object (subject of labor) and a transport device such as a belt conveyor, located in one housing (Figure 1).

Figure 1. Process Module

The scheme (Figure 1) shows:

1 — process module;

2 — subject of labor (workpiece);

3 — movable supports;

4 — conveyor belt;

5 — process equipment.

The module can be equipped with various process equipment and tools: a microwave emitter, a laser, a welding torch, milling cutters, drills, etc.

A new technical solution is that the conveyor belt can be used both to transport workpieces and to autonomously move the process module itself. The process module can use the conveyor for its own movement if the supports are folded (position A). Or it can move the workpiece when the supports are fully extended and the process module body is in position B.

The process module can maneuver by extending one of its supports during movement (Figure 2).

Figure 2. Maneuvering diagram for a mobile autonomous process module.

Figure 2 shows the scheme of the possible maneuvering of a process module. When one movable support is extended in the transport position, a moment is created that rotates the module around the support.

Such process modules can move autonomously, dock with each other, and thus form automated lines depending on the technological process regulations (Figure 3).

Figure 3. Scheme of Flexible Automatic Line

Figure 3 shows a diagram of an automated line consisting of autonomous process modules.

Process modules can be replaced or removed from the automated line as needed. Depending on the raw materials used, the production technology may change. In this case, a new process module will need to be replaced or added to the line. Such situations also arise during a change in technology or a module failure.

The flexible automated line [3, 4, 5] is equipped with process modules, transport robots, and a power station capable of generating and transmitting electricity wirelessly over short distances. The transport robots and process modules are equipped with batteries and solar panels, which provide autonomous operation for a specified period.

Discussion

The use of autonomous process modules and transport robots of various configurations will significantly reduce the initial development time of the production process and reduce the costs of creating comfortable conditions for personnel.

Organizing production in remote locations requires the use of workers who must install, configure, and operate process equipment. For construction workers to function normally, comfortable working and living conditions must be created from the outset [6], which requires significant investment of time, energy, and material resources. Comfortable conditions include living quarters equipped with sleeping areas, a kitchen, relaxation areas, a restroom, water supply, sewerage, heating, air conditioning, ventilation, and other equipment. [7]

Production facilities must also be equipped in accordance with labor protection and safety standards, which requires corresponding costs.

When calculating the economic impact of implementing the proposed automation tools, the reduction of human error risks should be taken into account [8].

Conclusion

In unfavorable or aggressive natural environments, the use of human labor presents a serious organizational challenge. The use of mobile autonomous process modules and transport robots in automated production lines offers the potential to significantly reduce project implementation time. The economic benefit lies in the reduced costs of providing housing and production infrastructure for workers. Flexible automated production facilities can be located in areas unsuitable for human habitation. This will reduce the industrial and transport burden on permanently populated areas.

The proposed approach to organizing the automated production of building materials and products from local raw materials will significantly reduce the costs of developing planets and other sites.

References

1. Hartley J. Flexible Automation in Japan. Germany: IFS. 2013. 264p.2. Handbook of Industrial Engineering: Technology and Operations Management. (2001). Great Britain: Wiley. 2796 p.

3. Talavage, J. Flexible Manufacturing Systems in Practice: Design: Analysis and Simulation. USA: CRC Press. 2020. 272 p.

4. Design of Flexible Production Systems – Methodologies and Tools. By T. Tolio. Berlin: Springer, 2009. 307 p.

5. Fokina D., Dzhamay E., Zinchenko A. Flexible prodaction systems as the basis for innovative development of industrial enterprises // Bulletin of the State University of Education. Series: Economics. 2024. №2, Р. р.113-121.

6. Zolochevsky I.S. .Labor protection: international and European requirements // Crimean Academic Bulletin. 2020. No. 13. pp. 64-69.

7. The Human Factors of Process Safety and Worker Empowerment in the Offshore Oil Industry: Proceedings of a Workshop. (2018). USA: National Academies Press.

8. Glendon, A. I., Clarke, S. (2018). Human Safety and Risk Management: A Psychological Perspective, Third Edition. (n.p.): CRC Press. 528 p.