Introduction

Global trends in the transport sector increasingly prioritize environmental sustainability, and under the framework of the “Green Transition,” it has become essential to reduce road congestion, reduce greenhouse gas emissions, develop efficient logistics systems, and shift cargo transport from road to rail, thus positioning rail freight as a key component and prompting developed countries to emphasize the railway sector in their transport policies. As noted by Bianca Pascariu (2025), the increasing importance of rail freight is making it an integral part of the transport system. Ulaanbaatar Railway Joint Venture Company (UBTZ JVC), which occupies a key position in the social and economic sector of Mongolia, has experienced growing demand for railway transport in recent years. While the company transported approximately 21-22 million tons of cargo annually during 2014–2017, this volume increased steadily, reaching 33.4 million tons in 2024.

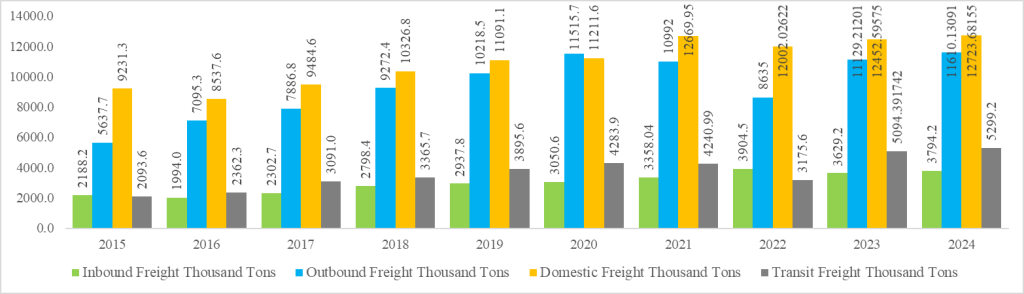

Source: (Unified Statistical Database).

Figure 1. Proportion of freight Traffic transported by rail

The proportion of rail freight transport volume by type of traffic, averaged over 2015–2024, shows that inbound cargo accounted for 73.3% (1,606 thousand tons), outbound cargo for 105.9% (5,972.4 thousand tons), domestic traffic for 37.8% (3,492.4 thousand tons), and transit cargo for 153.1% (3,205.6 thousand tons), respectively (Figure 1). Although railway companies should be prepared to meet the growing demand for freight transport, most privately owned branch lines have limited track capacity and inadequate loading and unloading equipment, resulting in operational difficulties such as a shortage of shunting locomotives, frequent locomotive failures, and an inability to fully meet freight orders. Therefore, it is essential to load wagons at freight yards in accordance with train marshalling plans, organize shunting operations efficiently, improve workflow coordination, and implement new technologies, with the implementation of these measures based on the theoretical principles. Frederick Winslow Taylor (1911), in his principles of scientific management, emphasized that production processes should be planned and organized scientifically, with work optimized according to labor schedules, time standards, and supervision. Henri Fayol (1916) outlined the management principles applicable to any companies, encompassing processes such as planning, organizing, leading, coordinating, and controlling. Other relevant approaches include eliminating non-value-added steps and reducing waste, waiting times, and unnecessary movements to enhance process efficiency (James P. Womack, Daniel T. Jones, & Roos, 1990); fundamentally redesigning business processes through the use of technology to significantly improve cost, time, and quality (Michael Hammer, James Champy, 1993); and applying movement management theories to develop efficient and well-coordinated process systems (D. May, 1994). The quality and efficiency of railway transport services directly depend on factors such as freight transportation time, promptness, and reliability. Timely delivery in line with customer expectations not only determines service quality but also serves as an important factor in the competitiveness of the sector. For Mongolia, the majority of cargo arriving from China at Zamyn-Uud station consists of containerized freight, construction materials, and other goods. Most imported and domestic cargo is transported in containers and handled at stations equipped with rail connections, customs-controlled areas, and open spaces suitable for container operations. At Zamyn-Uud station, the Transshipment Units and the Logistics Center carry out operations such as transferring cargo arriving by truck from the China onto wagons; receiving cargo and containers arriving in narrow-gauge wagons for domestic and international transport; transshipment; unloading and delivery; preparation of accompanying transport documents; accounting and reporting; and weighing and shunting via broad-gauge, narrow-gauge, or road vehicles.

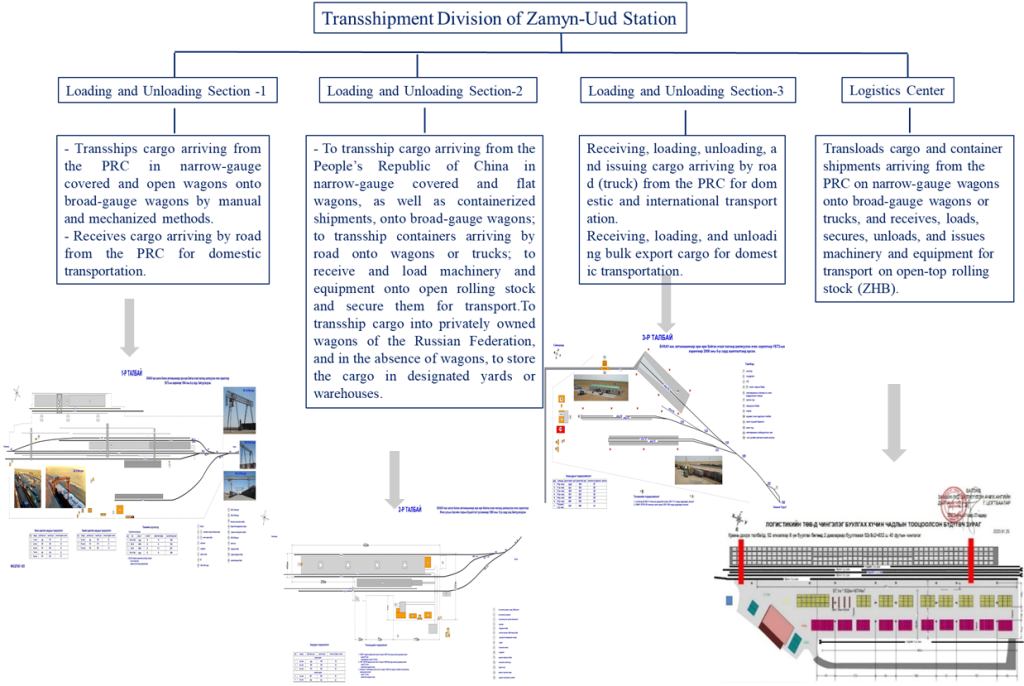

Source: Developed by the researcher

Figure 2. Transshipment Division of Zamyn-Uud Station

Within the Transshipment Division, Yards 1, 2, and 3 handle operations such as transferring cargo from narrow-gauge covered or flat wagons and container shipments onto broad-gauge wagons; transferring containers arriving by truck onto wagons or trucks; receiving and loading technical equipment and machinery onto open rolling stock; securing, unloading, issuing, and storing cargo; preparing transport and accompanying documents; handling financial issues; reporting; and overall organization of these operations (Technological Regulations of Zamyn-Uud Station, 2025).

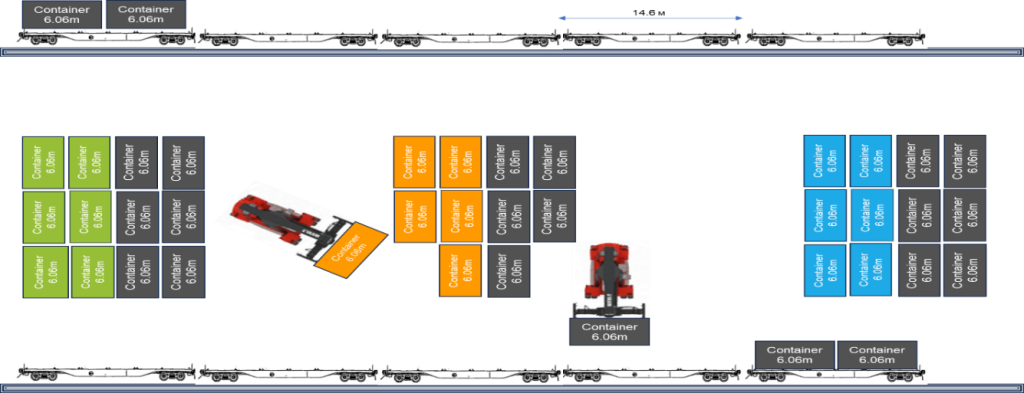

The 2nd workshop of the Transshipment Division handles operations such as transferring imported containers from narrow-gauge wagons to broad-gauge wagons using a self-propelled container loader; if wagons are unavailable, containers are first unloaded onto the designated yard and then loaded onto broad-gauge wagons. The yard has a capacity of 272 containers of 40 feet and 80 containers of 20 feet. Additionally, transfers from narrow-gauge covered wagons to broad-gauge wagons are also performed manually (Figure 3).

Source: Developed by the researcher

Figure 3. Container Yard of Workshop 2 at the Transshipment Division

At the loading and unloading 2nd workshop yard of the Transshipment Unit, imported containers with cargo are loaded from the container storage yard onto wagons by cargo handlers (Figure 4.) according to the import container consolidation plan.

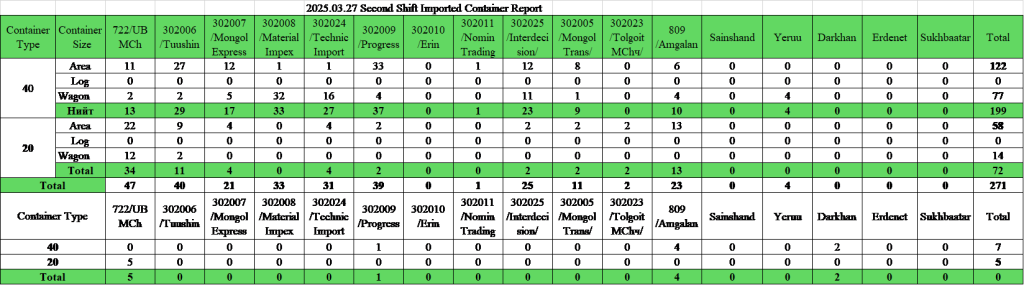

Source: Developed by the researcher

Figure 4. Import Container Consolidation

At UBTZ JVC stations, there are 12 companies with open, rail-connected, customs-controlled loading and unloading yards for container transportation operations. More than 300 companies without their own loading and unloading areas receive cargo at these authorized yards. Containers arriving by narrow-gauge wagons or trucks are loaded onto wagons according to the branch line owner’s code (e.g., 302007, 302001), grouped by the month and year of arrival and the branch line of unloading (Figure 4).

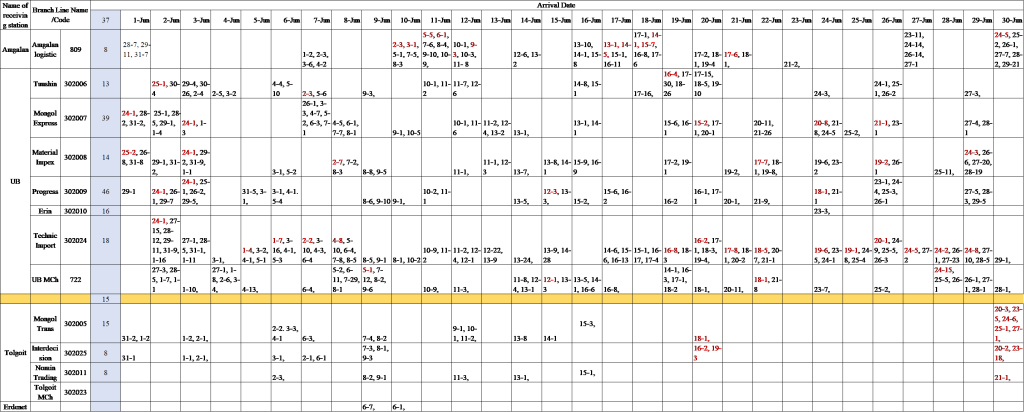

In process management theory based on cargo flow optimization (Business Process Optimization, Logistics Flow Management), the “First In, First Out” (FIFO) principle forms the foundation for logistics efficiency, balanced resource utilization, and fair service. When this principle is not followed, it adversely affects the supply chain by causing delays, reducing yard efficiency, and creating bottlenecks and backlogs. (Zajac, 2021) Therefore, an analysis was conducted on the loading sequence of containers received in June 2024 to examine whether the “First In – First Out” (FIFO) principle was being followed (Table 1).

Table 1.

Loading Sequence of Imported Containers arrived at Yard 2 of the Transshipment Division

The results of the study show that of the 1,790 containers received, 202 containers (9.7%) were not loaded in the order of their arrival by year, month, and day, with each container remaining on average 4.8 days. Meanwhile, containers that arrived later were loaded first.

Methodology

The broad-gauge railway track of the 2nd workshop container yard of the Transshipment Division has a capacity of 24 wagons. After loading is completed on all wagons, pulling them to the yard track and rearranging empty wagons takes at least 30 minutes. During this time, selecting containers by their date of arrival using a reach stacker takes about 1.5 minutes per container, allowing for up to 20 containers to be sorted. Therefore, failure to sort containers according to their arrival date results in increased delivery time for some containers and negatively affects the overall efficiency of the transportation process. This situation arises due to inadequate organization of the loading process, the absence of an appropriate mechanism for determining and monitoring the loading sequence, and leads to longer delivery times, reduced customer satisfaction, and inefficient utilization of the container yard capacity. Here, it is advisable to organize the container loading sequence in an optimal manner as illustrated in Figure 5.

Since this issue in loading organization may not only occur within the current month but may also affect subsequent operations, it is necessary to conduct a systematic analysis and take the following measures:

- Developing a FIFO-based algorithm that records each container’s arrival date, location, and status to automatically determine the loading sequence, and designing a software (system module) that enables automatic registration of container data;

- Organizing loading operations through algorithmic and operational planning methods based on information about destination stations, receiving sidings, unloading front capacity, and zoning, and systematically implementing and automating the “First In- First Out” (FIFO) principle;

- Minimizing decision-making dependency on human factors and establishing a data-driven management system;

- Formulating a cargo prioritization policy and developing a mechanism for early identification of urgent or time-sensitive cargo requiring prompt delivery;

- Introducing performance evaluation criteria (KPI) for measuring loading efficiency, compliance with loading sequence, and customer satisfaction, and integrating these indicators into the incentive system.

Source: Developed by the researcher

Figure 5. Diagram of the process for unloading import containers in the yard and loading them onto wagons

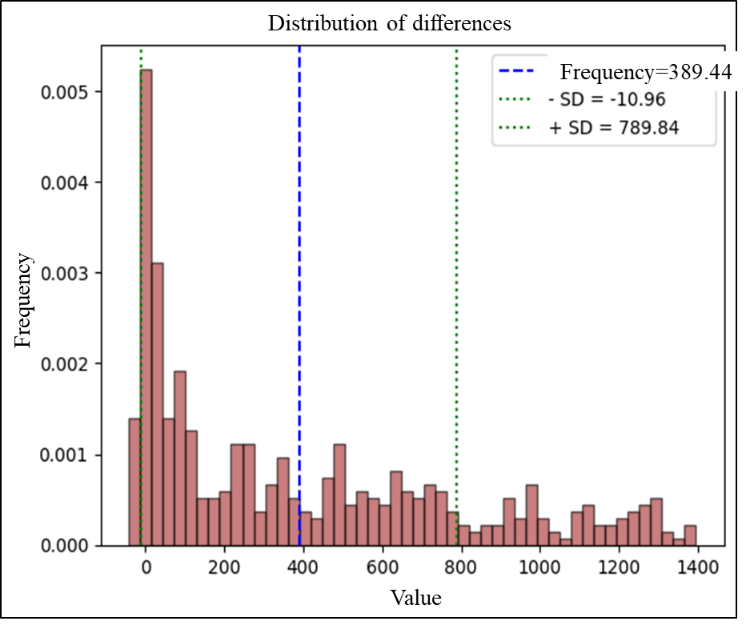

By implementing these measures step by step, it will be possible to optimize the container loading and delivery time, improve the quality of services provided to customers, and increase the efficiency of the utilization of the railway loading yard. In addition, by automating the loading decision-making process, a study and analysis were conducted to assess the potential reduction in shunting operations for sorting wagons on unloading station sidings and the resulting efficiency gains. The analysis was based on June 2024 data for 1,781 import containers unloaded at 12 terminals of the main stations, including Amgalan, Ulaanbaatar, and Tolgoit, along the Ulaanbaatar railway line (Table 2). Based on historical data, the total number of incoming containers, the distribution of containers destined for each terminal (Figure 6), the waiting time before the sidings are cleared for unloading, and the estimated cost savings after simulating the optimal allocation of containers during loading onto wagons by reach stacker at Zamyn-Uud station were calculated. (Table 4)

Table 2.

Number of containers dispatched from Zamyn-Uud in June 2024.

| No. | Terminal | Branch line code | Number of containers | Percent |

| 1 | UB MCh | 722 | 237 | 13.3071 |

| 2 | Tuushin | 302006 | 213 | 11.9596 |

| 3 | Mongol Express | 302007 | 153 | 8.59068 |

| 4 | Material Impex | 302008 | 194 | 10.8928 |

| 5 | Progress | 302009 | 128 | 7.18697 |

| 6 | Erin | 302010 | 3 | 0.16844 |

| 7 | Technic Import | 302024 | 484 | 27.1757 |

| 8 | Amgalan | 809 | 263 | 14.767 |

| 9 | Interdecision | 302025 | 40 | 2.24593 |

| 10 | Mongol Trans | 302005 | 55 | 3.08815 |

| 11 | Tolgoit MCh | 302023 | 0 | |

| 12 | Nomin Trading | 302011 | 11 | 0.61763 |

| Total | 1781 | |||

A histogram was created showing the distribution of waiting times during the unloading of containers from wagons by crane at the receiving station sidings, as well as the additional time spent while waiting for the unloading front on the sidings to be cleared (Figure 5).

Source: Developed by the researcher

Figure 6. Histogram showing the distribution of waiting times, including idle times on sidings and technological operation times

At Zamyn-Uud station, the cost of using the container handling mechanism (Kalmar) for loading and unloading on wagons is presented in Table 3. The cost of one hour of shunting operation at the unloading station for separating containers due to improper classification was calculated as 210,368 MNT. Without considering the capacity of the container yard or unloading track, the cost of waiting for the siding to be cleared when loading containers in bulk for a single receiver was estimated at 900 MNT per wagon per hour, or 20,000 MNT per wagon per day.

Table 3.

Hourly operation cost of the Kalmar (reach stacker)

| Loading/Unloading Mechanism Hourly Cost | TTTZ LLC | UBTZ JVC | |||||||

| Purpose | Cost/MNT | Purpose | Cost/MNT | ||||||

| Kalmar | Summer | 15L diesel / 3,140 | 47100 | 24L diesel | 75360 | ||||

| Winter | 18L diesel | 56520 | 25L diesel | 78500 | |||||

| Kalmar driver hourly rate | 17919 | 15000 | |||||||

| Total | 74439 | 93500 | |||||||

The following methods were used to optimize the allocation of the decision-making function:

- Random: Allocating containers in a random manner;

- Controlled: Allocating containers with a 0.7 probability that consecutive containers are assigned to the same terminal;

- Smart: Allocating containers at Zamyn-Uud based on their arrival date (“First In- First Out”) and their designated receiving terminal, ensuring that the allocation does not exceed the capacity of each terminal.

Results

By optimally organizing train assembly and loading operations at Zamyn-Uud station, taking into account destination stations, receiving sidings, unloading front capacity, and zoning, it is possible to assemble trains accurately following the “First In- First Out” (FIFO) principle, ensuring that containers arriving first are loaded first. This approach reduces the number of shunting operations required to position wagons on the sidings at the unloading station, thereby lowering related costs. Furthermore, the waiting time of loaded wagons for the unloading front to be cleared is shortened, decreasing waiting-related expenses.

To evaluate these effects, a simulation was developed in Python using the following functions:

- generate_containers: Creating containers with terminal allocations based on a probability distribution;

- generate_trains: Generating empty trains for cargo loading

- train_to_terminal_sequence: Analyzing the sequence of train allocations to terminals and implementing this process in code;

- count_transitions_load_containers_to_trains: Calculating the number of transitions when loading containers onto trains, with results presented in Table 4.

Table 4

Comparison of total costs across container loading alternatives

| Kalmar Operation Cost | Cost of sorting for unloading sidings | Waiting Time Cost | Delivery Cost | Total Cost | Savings | |

| Random | 25,712,500 | 96,332,250 | 1,078,260 | 100,957,500 | 224,080,510 | |

| Actual (70%) | 37,248,062 | 36,317,750 | 1,108,082 | 90,311,550 | 164,985,444 | |

| Optimized | 50,692,583 | 10,955,000 | 1,333,733 | 64,491,000 | 127,472,316 | 23% |

Monthly savings = 37,513,128 MNT

Annual savings = 450,157,536 MNT

By optimally marshalling trains at the loading station, the total cost can be minimized to approximately 127 million MNT. Compared with the Random allocation scenario, this reduces costs by about 97 million MNT, and compared with the Actual (70%) scenario, by about 38 million MNT, achieving a total savings of 23%.

To verify the accuracy of the Python-based total cost savings calculations, a simulation was conducted using the “Train Switch Optimizer” program, which confirmed the results.

The “Train Switch Optimizer” software system is designed to optimize container flow in railway cargo operations and improve the efficiency of shunting operations. The program operates through the following stages:

- Data Input: The program utilizes primary information such as the number of containers, destination terminals, arrival time, and loading/unloading conditions. It also accounts for the number of wagons per train (40–55 containers) and the capacity of each terminal. Cost data include indicators for loading, unloading, waiting time, and delivery expenses.

- Allocation Algorithm: Several decision-making methods are applied when allocating containers to wagons and terminals:

-Random allocation: Assigning containers in a completely random manner;

— Controlled allocation: Allocating containers with a 0.7 probability of being directed consecutively to the same terminal;

—Smart allocation: Optimally allocating containers based on arrival time (“First In- First Out”), designated unloading terminal, and terminal capacity constraints.

- Simulation and Calculation: The program simulates container flow according to the selected algorithm and calculates metrics such as average delay time, terminal utilization rate, shunting efficiency, time reduction percentage, total cost, and potential savings.

- Dashboard: The results are visualized in a dashboard format, using charts and tables. This provides a comprehensive view of terminal capacity utilization, daily throughput, average waiting time, total costs, and efficiency trends.

- Decision-making: Based on the analysis, management can determine which allocation method (Random, Controlled, or Smart) yields the lowest cost, the greatest time savings, and the highest shunting efficiency, thereby supporting optimal decision-making.

The Train Switch Optimizer is a decision support system aimed at enhancing the management of railway container transportation by simulating container flows based on input data, selecting the most efficient allocation scenario, calculating performance metrics, and visualizing the results.

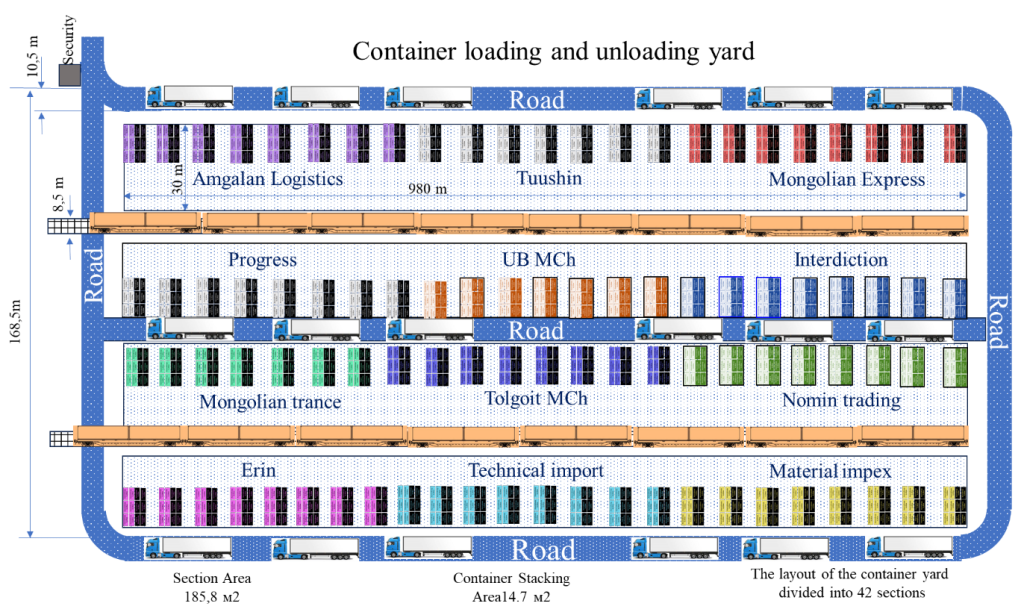

In accordance with the Government of Mongolia’s 2024–2028 Action Program, the “Vision-2050” long-term development strategy, the “New Revival Policy”, and the Master Plan for Ulaanbaatar City’s development through 2030, a new railway branch line is planned along the Bagakhangai–Khushgiin Khundii corridor, alongside the establishment of economic free zones, industrial zones, and transport-logistics hubs (B. Tamir, A. Baldandorj, 2025). Relocating these terminals to the Khushgiin Khundii transport-logistics center is projected to handle an anticipated import cargo volume of 3.5–20 million tons, effectively preventing an estimated 316–1,800 large trucks per day from entering Ulaanbaatar’s urban traffic (B. Delgersaikhan, 2025).

Source: Developed by the researcher

Figure 7. Layout of the transport-logistics center in Khushgiin Khundii

Within the framework of the above policies, the establishment of a new economic free zone, industrial zone, and transport-logistics hub along the Bagakhangai–Khushgiin Khundii corridor, together with the commissioning of a centralized terminal consolidating Ulaanbaatar’s existing terminals, enables loaded containers from Zamyn-Uud station to be optimally allocated for loading according to the sequence of transport and logistics organizations shown in Figure 7 using the Train Switch Optimizer program. This approach ensures correct train composition, streamlines loading and unloading operations at the terminal, increases the utilization and productivity of equipment-particularly Kalmar cranes-and reduces operational costs, thereby delivering direct economic benefits.

Implementing new technology in loading operations is a key step to enhancing railway efficiency, safety, and productivity. At the same time, potential risks must be anticipated and appropriate mitigation measures planned. Risk analysis identifies internal and external factors that could affect both the transition process and daily operations, and determines strategies to minimize their impact.

During system implementation, operational risks such as workflow disruptions, employee resistance, and challenges in system integration may arise (Figure 8).

The new system should be introduced in phases, supported by comprehensive measures such as employee training and preparation of backup procedures. Operational risks, including equipment malfunctions, adverse weather, and regulatory changes, should be foreseen in advance. Establishing flexible management and maintenance systems, and planning in advance the measures to be taken in case of unexpected situations, is important.

Conclusion

By optimally planning loading operations according to the destination station, the zoning of receiving sidings, and the capacity of unloading tracks, arranging the sidings by coding, and improving the transshipment technology at Zamyn-Uud station, it becomes possible to enhance the utilization of shunting locomotives at the station and reduce idle time and rearrangement periods for local wagons.

By properly marshalling trains at the loading station, total costs can be reduced to approximately 127 million MNT, saving around 97 million MNT compared to the Random case and 38 million MNT compared to the actual case, achieving a 23% overall cost reduction. These results demonstrate that proper train marshalling is an effective strategy for improving railway shunting efficiency and reducing operational expenses.

Based on the research analysis, implementing the optimization has proven to be highly efficient in terms of finance, operations, risk management, and competitiveness, while being easy to manage and feasible to execute. Therefore, further expanding and applying this optimization solution represents an important step in contributing significant value to the development of the sector.

Introducing new technology into shunting operations is a vital measure to enhance railway efficiency, safety, and productivity. However, it is essential to anticipate potential risks that may arise and to plan appropriate management measures in advance. Risk analysis plays a key role in identifying internal and external factors that could affect both the transition process and daily operations, as well as in determining appropriate measures to reduce adverse effects.

References

1. Bianca Pascariu. (2025). Formulation and solution framework for real-time railway traffic. IET Intelligent Transport Systems, e12610.2. D.May, A. (1994). Traffic Management from Theory to Practice: Past, Present, Future. Transportation Research Record No. 1457, 5-14.

3. Fayol, H. (1916 оны November 21). General and Industrial Management. Internet Archive: https://archive.org/details/generalandindust031038mbp-ээс Гаргасан

4. James P. Womack, Daniel T. Jones, Daniel Roos. (1990). The Machine That Changed the World. New York: Rawson Associates.

5. Michael Hammer, James Champy. (1993). Reengineering the Corporation: A Manifesto for Business Revolution. New York: HarperCollins imprint.

6. Michael Hammer, James Champy. (1993). Reengineering the Corporation: A Manifesto for Business Revolution. New York: HarperCollins imprint.

7. Taylor, F. W. (1911 оны June 1). The Principles of Scientific Management. Project Gutenberg: https://www.gutenberg.org/ebooks/6433-ээс Гаргасан

8. Zajac, M. (2021). The model of reducing operations time at a container terminal by assigning places and sequence of operations. Applied Sciences, 1-13.

9. Delgersaikhan, B. (2025, April 25). The Bagakhangai–Khushgiin Khundii branch line will be one of the major national construction projects. Ministry of Road and Transport Development of Mongolia. Retrieved from https://mrt.gov.mn/i/4513

10. Tamir, B., & Baldandorj, A. (2025). Feasibility Study for the Bagakhangai–Khushgiin Khundii Branch Railway Line. Ulaanbaatar: Mongolian Railway.

11. (2025). Technological Regulations of Zamiin-Uud Station. Dornogovi Province: Zamiin-Uud Station.